TMC2226 vs TMC2209: What are Differences

Published: Dec 08, 2023

Published: Dec 08, 2023

Contents

TMC2226 vs TMC2209: Overview

The TMC2226 and TMC2209 are advanced motor driver ICs for two-phase stepper motors. Both offer silent operation, precise motion control, and protective features, but the TMC2226 emphasizes noise-free functionality and optimized efficiency, while the TMC2209 focuses on compatibility, quietness, and robust protective capabilities.

TMC2226

The TMC2226, designed for two-phase stepper motors, utilizes TRINAMIC's StealthChop2 technology for noiseless operation, optimal efficiency, and maximum torque. It provides rapid current regulation, optional SpreadCycle integration, and StallGuard for sensorless homing. Featuring built-in power MOSFETs managing up to 2A RMS, it ensures protection and diagnostics. Its user-friendly UART interface enables easy tuning and application storage in OTP memory. Positioned as a leading STEP/DIR stepper motor driver, it delivers silent precision, making it a cost-effective, competitive solution.

TMC2209

The TMC2209 is a low-noise motor driver designed for two-phase stepper motors, featuring pinning akin to legacy drivers like the TMC2208 for improved compatibility. Utilizing TRINAMIC's StealthChop2 technology, it ensures quiet, efficient, and high-torque operation. Its rapid current regulation and optional SpreadCycle integration enable dynamic motion capabilities.

Incorporating StallGuard for sensorless homing, it handles motor currents up to 2A RMS, supported by protective and diagnostic features. The UART interface simplifies tuning and control, allowing storage of application settings in OTP memory. Positioned as a leading STEP/DIR stepper motor driver, it offers silent, precise, and cost-effective solutions.

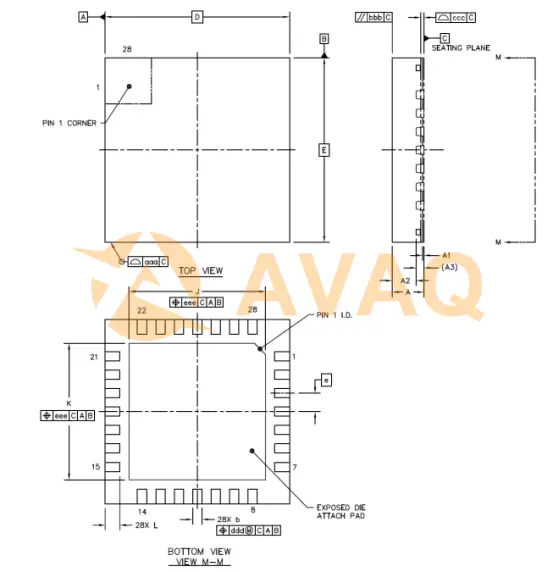

TMC2226 vs TMC2209: Pinout

TMC2226 Pinout

Pin Configuration

|

Pin Number |

Type |

Function |

|

OB1 |

1 |

Motor coil B output 1 |

|

BRB |

2 |

Sense resistor connection for coil B. Place the sense resistor to GND near the pin. Tie to GND when using the internal sense resistor. |

|

VS |

3, 26 |

Motor supply voltage. Provide filtering capacity near the pin with the shortest possible loop to the GND pad. |

|

OB2 |

4 |

Motor coil B output 2 |

|

ENN |

5 |

DI Enable not input. The power stage becomes switched off (all motor outputs floating) when this pin becomes driven to a high level. |

|

GND |

6, 22 |

GND. Connect to the GND plane near the pin. |

|

CPO |

7 |

Charge pump capacitor output. |

|

CPI |

8 |

Charge pump capacitor input. Tie to CPO using a 22nF 50V capacitor. |

|

VCP |

9 |

Charge pump voltage. Tie to VS using a 100nF capacitor. |

|

SPREAD |

10 |

DI (pd) Chopper mode selection: Low=StealthChop, High=SpreadCycle (may be left unconnected) |

|

5VOUT |

11 |

Output of internal 5V regulator. Attach a 2.2µF to 4.7µF ceramic capacitor to GND near the pin for best performance. Provide the shortest possible loop to the GND pad. |

|

MS1_AD0 |

12 |

DI (pd) Microstep resolution configuration (internal pull-down resistors). MS2, MS1: 00: 1/8, 01: 1/32, 10: 1/64, 11: 1/16. For UART based configuration selection of UART Address 0…3 MS2_AD1 |

|

DIAG |

15 |

DO Diagnostic and StallGuard output. High level upon stall detection or driver error. Reset error condition by ENN=high. |

|

INDEX |

16 |

DO Configurable index output. Provides an index pulse. |

|

CLK |

17 |

DI CLK input. Tie to GND using a short wire for internal clock or supply an external clock. |

|

PDN_UART |

18 |

DIO Power down not control input (low = automatic standstill current reduction). Optional UART Input/Output. Power down function can be disabled in UART mode. |

|

VCC_IO |

19 |

3.3V to 5V IO supply voltage for all digital pins (does not supply IC logic part). |

|

STEP |

20 |

DI STEP input |

|

VREF |

21 |

AI Analog reference voltage for current scaling or reference current for use of internal sense resistors (optional mode). |

|

DIR |

23 |

DI (pd) DIR input (internal pull-down resistor). |

|

STDBY |

24 |

DI (pd) STANDBY input. Pull up to disable the driver internal supply regulator. This will bring the driver into a low power dissipation state. 100kOhm pulldown. (may be left unconnected). Hint: Also shut down VREF voltage and ENN to 0V during standby. |

|

OA2 |

25 |

Motor coil A output 2 |

|

BRA |

27 |

Sense resistor connection for coil A. Place the sense resistor to GND near the pin. Tie to GND when using the internal sense resistor. |

|

OA1 |

28 |

Motor coil A output 1 |

|

- |

13 |

Unused. May be connected to GND for better PCB routing. |

|

Exposed die pad |

- |

Connect the exposed die pad to a GND plane. Provide as many vias as possible for heat transfer to the GND plane. Serves as the GND pin for power drivers and analogue circuitry. |

TMC2209 Pinout

Pin Configuration

|

Pin Number |

Type |

Function |

|

OB2 |

1 |

Motor coil B output 2 |

|

ENN |

2 |

DI Enable not input. The power stage becomes switched off (all motor outputs floating) when this pin becomes driven to a high level. |

|

GND |

3, 18 |

GND. Connect to GND plane near pin. |

|

CPO |

4 |

Charge pump capacitor output. |

|

CPI |

5 |

Charge pump capacitor input. Tie to CPO using a 22nF 50V capacitor. |

|

VCP |

6 |

Charge pump voltage. Tie to VS using a 100nF capacitor. |

|

SPREAD |

7 |

DI (pd) Chopper mode selection: Low=StealthChop, High=SpreadCycle (may be left unconnected) |

|

5VOUT |

8 |

Output of internal 5V regulator. Attach a 2.2µF to 4.7µF ceramic capacitor to GND near the pin for best performance. Provide the shortest possible loop to the GND pad. |

|

MS1_AD0 |

9 |

DI (pd) Microstep resolution configuration (internal pull-down resistors). MS2, MS1: 00: 1/8, 01: 1/32, 10: 1/64, 11: 1/16. For UART based configuration selection of UART Address 0…3 MS2_AD1 |

|

DIAG |

11 |

DO Diagnostic and StallGuard output. High level upon stall detection or driver error. Reset error condition by ENN=high. |

|

INDEX |

12 |

DO Configurable index output. Provides index pulse. |

|

CLK |

13 |

DI CLK input. Tie to GND using a short wire for internal clock or supply external clock. |

|

PDN_UART |

14 |

DIO Power down not control input (low = automatic standstill current reduction). Optional UART Input/Output. Power down function can be disabled in UART mode. |

|

VCC_IO |

15 |

3.3V to 5V IO supply voltage for all digital pins (does not supply IC logic part). |

|

STEP |

16 |

DI STEP input |

|

VREF |

17 |

AI Analog reference voltage for current scaling or reference current for use of internal sense resistors (optional mode). |

|

DIR |

19 |

DI (pd) DIR input (internal pull-down resistor). |

|

STDBY |

20 |

DI (pd) STANDBY input. Pull up to disable driver internal supply regulator. This will bring the driver into a low power dissipation state. 100kOhm pulldown. (may be left unconnected). Hint: Also shut down VREF voltage and ENN to 0V during standby. |

|

VS |

22, 28 |

Motor supply voltage. Provide filtering capacity near the pin with the shortest possible loop to the GND pad. |

|

OA2 |

21 |

Motor coil A output 2 |

|

BRA |

23 |

Sense resistor connection for coil A. Place the sense resistor to GND near the pin. Tie to GND when using the internal sense resistor. |

|

OA1 |

24 |

Motor coil A output 1 |

|

- |

25 |

Unused. May be connected to GND for better PCB routing. |

|

OB1 |

26 |

Motor coil B output 1 |

|

BRB |

27 |

Sense resistor connection for coil B. Place the sense resistor to GND near the pin. Tie to GND when using the internal sense resistor. |

|

Exposed die pad |

- |

Connect the exposed die pad to a GND plane. Provide as many vias as possible for heat transfer to the GND plane. Serves as the GND pin for power drivers and analogue circuitry. |

TMC2226 vs TMC2209: Specifications

TMC2226 Specifications

- Manufacturer: Analog Devices Inc.

- Motor Type - Stepper: Bipolar

- Motor Type - AC, DC: N/A

- Function: Integrated Driver - Control and Power Stages Combined

- Output Configuration: Step/Direction

- Interface: Step/Direction, UART

- Technology: Power MOSFET

- Step Resolution: 1 to 1/256 microstepping

- Applications: General Purpose

- Current - Output: Up to 2A

- Voltage - Supply: 3.3V to 5V

- Voltage - Load: 4.75V to 29V

- Operating Temperature: -40°C to 125°C (TJ)

- Mounting Type: Surface Mount

- Package / Case: 28-TSSOP

TMC2209 Specifications

- Manufacturer: Analog Devices Inc.

- Product: Stepper Motor Controllers / Drivers

- Type: 2-Phase

- Operating Supply Voltage: 4.6V to 5.25V

- Output Current: 2.8A

- Operating Supply Current: 7.5mA

- Minimum Operating Temperature: -40°C

- Maximum Operating Temperature: +125°C

- Mounting Style: Surface Mount (SMD/SMT)

- Package / Case: QFN-28

- Brand: ADI Trinamic

- Development Kit: TMC2209-EVAL

- Load Voltage Rating: 6V to 29V

- Operating Frequency: 12MHz

- Power Dissipation (Pd): 1.4W

TMC2226 vs TMC2209: Features

TMC2226 Features

- Support for 2-phase stepper motors with up to 2.8A peak coil current (2A RMS)

- STEP/DIR Interface accommodating 8, 16, 32, or 64 microstep pin configurations

- Smooth operation with 256 microsteps using MicroPlyer™ interpolation

- StealthChop2™ technology for silent motor operation

- SpreadCycle™ offering highly dynamic motor control

- StallGuard4™ enabling load and stall detection in StealthChop mode

- CoolStep™ for current control and up to 75% energy savings

- Low RDSon with LS and HS at 170mΩ (typical at 25°C)

- Operating voltage range: 4.75V to 29V DC

- Low Power Standby mode adhering to standby energy regulations

- Option for internal sense resistor, eliminating the need for external resistors

- Passive Braking, Freewheeling, and automatic power down features

- Single Wire UART & OTP for advanced configuration capabilities

- Integrated Pulse Generator enabling standalone motion

- Full suite of Protection & Diagnostics

- Thermally optimized HTSSOP package for enhanced optical inspection

TMC2209 Features and benefits

- Compatible with 2-phase stepper motors, supporting up to 2.8A peak coil current (2A RMS)

- STEP/DIR Interface offering 8, 16, 32, or 64 microstep pin settings

- Smooth operation enabled by 256 microsteps using MicroPlyer™ interpolation

- StealthChop2™ ensuring silent motor operation

- SpreadCycle™ providing highly dynamic motor control

- StallGuard4™ facilitating load and stall detection for StealthChop mode

- CoolStep™ feature for current control, allowing up to 75% energy savings

- Operating voltage range of 4.75V to 29V DC

- Low RDSon with LS and HS at 170mΩ (typical at 25°C), minimizing heat generation

- Low Power Standby mode complying with standby energy regulations

- Option for an internal sense resistor, eliminating the need for external resistors

- Features such as Passive Braking, Freewheeling, and automatic power down

- Single Wire UART & OTP providing advanced configuration capabilities

- Integrated Pulse Generator enabling standalone motion

- Complete suite of Protection & Diagnostics

- Compact QFN package design with a large heat slug for optimized thermal management.

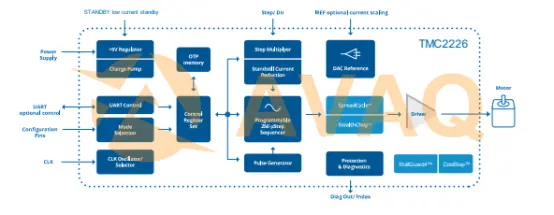

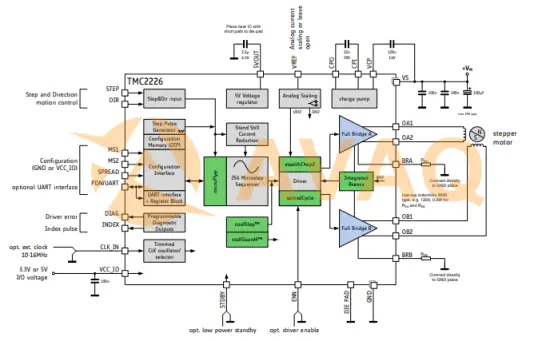

TMC2226 vs TMC2209: Application and Block Diagram

TMC2226 and TMC2209, being part of the TMC22xx series, share identical application, block diagrams, and basic application block diagrams.

Application

- Compatible Design Upgrade

- 3D Printers

- Printers, POS

- Office and home automation

- Textile, Sewing Machines

- CCTV, Security

- ATM, Cash recycler

- HVAC

- Battery Operated Equipment

BLOCK DIAGRAM

Basic application block diagram

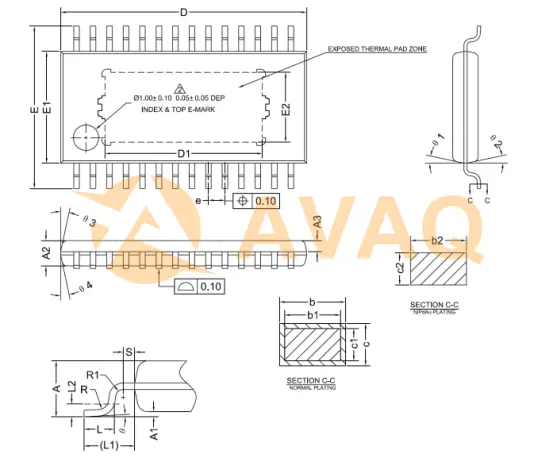

TMC2226 vs TMC2209: Package

TMC2226 Package

TMC2209 Package

TMC2226 vs TMC2209: Similarities and Differences

Both the TMC2226 and TMC2209 share a robust set of features suitable for driving stepper motors. The key differences lie in their operating voltage, temperature range, and package design, catering to different application needs and mounting preferences. Here's a comparison between the TMC2226 and TMC2209 stepper motor driver ICs:

Similarities:

- Motor Compatibility: Both support 2-phase stepper motors with up to 2.8A coil current (peak), 2A RMS.

- Step/Direction Interface: They utilize the STEP/DIR interface with various microstep settings (8, 16, 32, or 64).

- Microstepping: They offer smooth operation with up to 256 microsteps via MicroPlyer™ interpolation.

- StealthChop2™ Technology: Ensures silent motor operation.

- SpreadCycle™ Control: Provides highly dynamic motor control.

- Stall Detection: Both integrate StallGuard4™ for load and stall detection in StealthChop mode.

- CoolStep™ Control: Enables current control for energy savings (up to 75%).

- Voltage Range: Operate within a voltage range of 4.75V to 29V DC.

- Low RDSon and Heat-Up: Feature low RDSon with optimized heat dissipation.

- Standby Power Modes: Support low power standby modes to comply with energy regulations.

- UART & OTP Configuration: Offer single-wire UART and OTP for advanced configuration.

- Integrated Pulse Generator: Enable standalone motion with an integrated pulse generator.

- Protection & Diagnostics: Both come with comprehensive protection and diagnostic features.

- Internal Sense Resistor Option: Allow an internal sense resistor option without the need for external resistors.

- Power Down Features: Support passive braking, freewheeling, and automatic power down.

Main Differences:

- Operating Voltage: TMC2226 operates within a voltage range of 3.3V to 5V, while TMC2209 operates between 4.6V to 5.25V.

- Operating Temperature: TMC2226's operating temperature spans -40°C to 125°C, whereas TMC2209 operates from -40°C to +125°C.

- Mounting Style & Package: TMC2226 comes in a 28-TSSOP package, whereas TMC2209 is available in a QFN-28 package.

- Package Design: TMC2226 features a thermally optimized HTSSOP package for optical inspection, while TMC2209 has a compact QFN package with a large heat slug.

Manufacturer

Both the TMC2226 and TMC2209 stepper motor driver ICs were originally developed and manufactured by Trinamic, a company specialized in motion control and motor drive technologies. Trinamic was acquired by Analog Devices Inc. in 2021. Therefore, while Trinamic was the original developer and manufacturer, Analog Devices Inc. oversees these products post-acquisition.

Analog Devices Inc. (ADI) is a multinational semiconductor company known for its comprehensive range of analog, mixed-signal, and digital signal processing technologies. ADI specializes in providing high-performance solutions for a wide array of industries, including automotive, communications, healthcare, industrial, and consumer electronics. They offer a diverse portfolio of products, including data converters, amplifiers, sensors, processors, and power management components, catering to various applications requiring precision and reliability in signal processing and control.

Datasheet PDF

Further Reading: TMC5160 vs TMC2209: What are Differences 2023>>

FAQ

FAQ

- Can I use these drivers interchangeably in my application?

- While both drivers offer advanced features, differences in motor current ratings and additional features like stall detection might influence your choice. Ensure compatibility with your specific motor and application requirements before selecting one over the other.

- What are the common applications for these drivers?

- Both drivers are used in 3D printers, CNC machines, robotic arms, and various motion control systems requiring precise and quiet stepper motor control.

- When should I use the TMC2226 or TMC2209 in a stepper motor application?

- Choose the TMC2226 for applications requiring higher motor currents and superior stall detection capabilities. Opt for the TMC2209 for applications where lower to moderate motor currents are sufficient and sensorless homing/stall detection is needed.

TMC2226-SA-T In Stock: 3232 $1.661

Popular Industry Focus

Popular Industry Focus

Related Parts

-

BM2P129TF-E2

ROHM Semiconductor

Switching Voltage Regulators Intgrd PWM 8-12.97V Auto Rstrt SOP8

-

ISL6120CBZA

Renesas Technology Corp

Hot Swap Voltage Controllers W/ANL 8LD +5V SINGLE HOT PLUG CONTROLER

-

TPS65073RSLT

Texas Instruments, Inc

5-Channel Power Management IC (PMIC) with 3 DC/DCs, 2 LDOs in 6x6mm QFN

-

AP1661AP-G1

Diodes Inc

Power Factor Correction - PFC

-

TPS60311DGS

Texas Instruments, Inc

Charge Pump Switching Regulator IC Positive Fixed 2Vin, 3V 2 Output 40mA, 20mA 10-TFSOP, 10-MSOP (0.118", 3.00mm Width)

-

TOP258GN-TL

Power Integrations, Inc

AC/DC Converters Off-Line Switcher IC 35W/50W PK

-

P9242-RBNDGI8

Renesas Technology Corp

Wireless Power Transmitter PMIC 48-VFQFPN (6x6)

-

TOP259YN

Power Integrations, Inc

TOPSwitch-HX: 700V 238W Enhanced EcoSmart™ Integrated Off-Line Switcher-TO220-7C

-

NCP1380BDR2G

ON Semiconductor, LLC

Controller, Quasi-Resonant Current Mode

-

AP2301AFGE-7

Diodes Inc

Power Switch/Driver 1:1 P-Channel 2A U-DFN3030-8 (Type E)

-

W83310DG

Nuvoton Technology Corporation

Bus Termination Regulator | IC REG CONV INTEL 1OUT 8ESOP

-

TS51224-M000WCSR

Semtech Corporation

Wearables PMIC 25-WCSP (2.3x2.3)

-

STPD01PUR

STMicroelectronics, Inc

- Converter, USB Voltage Regulator IC 1 Output 24-QFN (3x4)

-

MAX1044CSA+T

Analog Devices, Inc

Charge Pump Switching Regulator IC Positive or Negative Fixed -Vin, nVin, Vin/2 1 Output 20mA 8-SOIC (0.154", 3.90mm Width)

-

XC6120C232HR-G

TOREX SEMICONDUCTOR LTD

Supervisory Circuits

Update Time: Mar 01, 2024 Consumer Electronics

Update Time: Mar 01, 2024 Consumer Electronics