TMC5160 vs TMC2209: What are Differences 2023

Published: Oct 27, 2023

Published: Oct 27, 2023

Contents

Introduction to TMC5160 and TMC2209

The TMC5160 and TMC2209 are both motor driver integrated circuits (ICs) produced by Trinamic, a company that specializes in motion control and motor drive technology. These ICs are designed for controlling stepper motors, and they offer various advanced features to enhance the performance and efficiency of stepper motor systems.

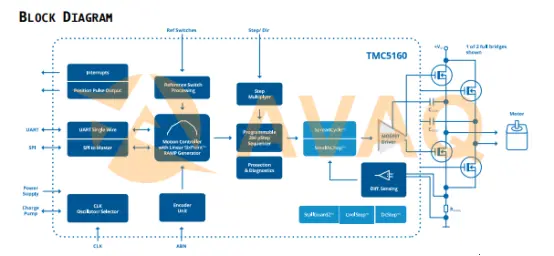

The TMC5160/TMC5160A is a high-power stepper motor controller and driver IC with serial communication interfaces. It offers a flexible ramp generator for precise target positioning and features the industry's most advanced stepper motor driver. By using external transistors, it enables the creation of highly dynamic, high-torque motor systems.

This driver, built on TRINAMIC's sophisticated SpreadCycle and StealthChop technology, ensures completely silent operation along with maximum efficiency and optimal motor torque. With its compact design and high integration, it enables the development of cost-effective, miniaturized, and scalable systems, simplifying the learning curve while delivering top-notch performance.

The TMC2209 is an ultra-quiet motor driver IC designed for two-phase stepper motors. Its pinout is compatible with several legacy drivers and the TMC2208. Featuring TRINAMIC's advanced StealthChop2 technology, it ensures noiseless motor operation, maximum efficiency, and optimal torque. With fast current regulation and the option to use SpreadCycle, it allows for highly dynamic motion and includes features like StallGuard for sensorless homing.

The integrated power MOSFETs can handle motor currents up to 2A RMS while providing protection and diagnostic capabilities for robust and reliable performance. Its straightforward UART interface offers tuning and control options, and application settings can be stored in OTP memory. As part of the industry's most advanced STEP/DIR stepper motor driver family, the TMC2209 enhances designs with noiseless and precise operation, making it a cost-effective and highly competitive solution.

TMC5160 vs TMC2209: Specifications and Features

TMC5160

- Designed for 2-phase stepper motors with coil currents ranging from 1 to several 10A.

- Features a motion controller with the SixPoint™ ramp algorithm for precise motor control.

- Supports Step/Dir interface with microstep interpolation using MicroPlyer™.

- Offers a wide voltage range of 8 to 60V DC for versatile power supply compatibility.

- Provides communication options with both SPI and Single Wire UART interfaces.

- Includes an encoder interface and two Ref.-Switch Inputs for precise positioning and limit switch functionality.

- Achieves the highest resolution with support for up to 256 microsteps per full step.

- Incorporates StealthChop2™ technology for quiet operation and smooth motion.

- Utilizes resonance dampening for mitigating mid-range resonances.

- Employs SpreadCycle™ for highly dynamic motor control.

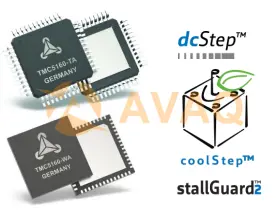

- Features DcStep™ for load-dependent speed control, enhancing efficiency.

- Utilizes StallGuard2™ for high-precision sensorless motor load detection.

- Implements CoolStep™ current control for energy savings of up to 75%.

- Offers passive braking and freewheeling modes for added functionality.

- Ensures full protection and diagnostics for reliable operation.

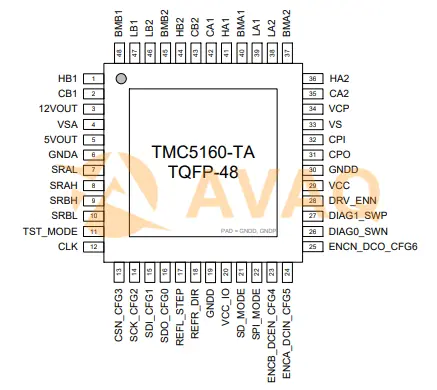

- Maintains a compact form factor with options for a TQFP48 package or an 8x8mm² QFN package, suitable for various applications.

TMC2209

- Designed for 2-phase stepper motors with a coil current of up to 2.8A at peak and 2A RMS.

- Supports a versatile STEP/DIR interface with selectable microstep settings (8, 16, 32, or 64) for precise motor control.

- Ensures smooth and precise motion with 256 microsteps through MicroPlyer™ interpolation.

- Provides noiseless motor operation with StealthChop2™ technology, making it suitable for quiet environments.

- Utilizes SpreadCycle™ for highly dynamic motor control.

- Features StallGuard4™ for load and stall detection, enhancing reliability, particularly in StealthChop mode.

- Incorporates CoolStep™ current control for energy savings of up to 75%.

- Offers low RDSon and low heat-up characteristics for efficient and cool operation (typical values of 170mΩ at 25°C).

- Supports a voltage range from 4.75V to 29V DC, accommodating various power supply configurations.

- Features a low-power standby mode to comply with standby energy regulations.

- Includes an option for an internal sense resistor, eliminating the need for external sense resistors.

- Offers additional functionality, such as passive braking, freewheeling, and automatic power down.

- Supports Single Wire UART communication and OTP for advanced configuration options.

- Integrates a pulse generator for standalone motion control.

- Provides full protection and diagnostics, ensuring reliable motor operation.

- Maintains a compact form factor with a QFN package that includes a large heat slug for efficient heat dissipation.

TMC5160 vs TMC2209: Specifications and Features

|

Feature |

TMC5160 |

TMC2209 |

|

Suitable for |

2-phase stepper motors (1 to several 10A) |

2-phase stepper motors (up to 2.8A peak) |

|

Voltage Range |

8V to 60V DC |

4.75V to 29V DC |

|

Communication Interfaces |

SPI & Single Wire UART |

Single Wire UART & OTP |

|

Microstepping Support |

Up to 256 microsteps per full step |

Up to 256 microsteps by MicroPlyer™ |

|

Special Control Features |

SixPoint™ ramp, Resonance Dampening, DcStep™ |

StallGuard4™, CoolStep™ |

|

Noise Operation |

StealthChop2™ |

StealthChop2™ |

|

Current Control |

CoolStep™ for energy savings |

CoolStep™ for energy savings |

|

Protection & Diagnostics |

Full Protection & Diagnostics |

Full Protection & Diagnostics |

|

Package Size |

Compact 7x7mm² TQFP48 package |

Compact QFN package with large heat slug |

TMC5160 vs TMC2209: Pinout

TMC5160 Pin Assignments

TMC2209 Pin Assignments

TMC5160 vs TMC2209: Block Diagram

TMC5160 Block Diagram

TMC2209 Block Diagram

TMC5160 vs TMC2209: Application

TMC5160 Application

High-Power Stepper Motors: The TMC5160 is suitable for applications that require driving high-power stepper motors with coil currents ranging from 1 to several 10A. This makes it a good choice for applications where higher torque and power are needed, such as industrial automation and CNC machines.

Precise Positioning: It offers features like SixPoint™ ramp, high microstepping resolution (up to 256 microsteps per full step), and encoder interface, making it suitable for applications where precise and smooth positioning is critical.

Quiet Operation: With features like StealthChop2™ and resonance damping, the TMC5160 provides noiseless operation, making it ideal for applications where low noise is essential, such as 3D printers and medical devices.

Advanced Control: Its advanced control algorithms and communication interfaces (SPI and Single Wire UART) make it a good fit for applications that require fine-tuned control and diagnostics.

TMC2209 Application

Low to Medium Power Stepper Motors: The TMC2209 is designed for driving 2-phase stepper motors with coil currents of up to 2.8A (peak) or 2A RMS. It is suitable for applications with lower power requirements, such as 3D printers, smaller CNC machines, and robotics.

Cost-Effective Solutions: TMC2209 offers a balance between performance and cost, making it a preferred choice for applications where cost-effectiveness is a priority.

Silent Operation: Like the TMC5160, it incorporates StealthChop2™ technology, providing silent motor operation. This is beneficial in applications where noise reduction is desired, especially in consumer electronics and small-scale automation.

Ease of Use: TMC2209's straightforward STEP/DIR interface and support for MicroPlyer™ interpolation simplify the integration process, making it a good choice for hobbyist and entry-level applications.

Energy Efficiency: It features CoolStep™ current control, which can save up to 75% energy. This is advantageous in applications where energy efficiency is a concern.

TMC5160 vs TMC2209: Application Circuit

TMC5160 Standard Application Circuit

The standard application circuit is designed to keep the number of additional components to a minimum. Eight MOSFETs are carefully chosen based on the desired current, voltage requirements, and package type. To set the motor coil current, two sense resistors are employed, and Chapter 9 provides guidance on selecting the appropriate sense resistor values.

For effective power supply filtering, it is crucial to use low-equivalent series resistance (ESR) capacitors. It is recommended to have a minimum capacitance of 100µF per ampere of coil current located in close proximity to the power bridge for optimal performance. These capacitors must be capable of handling the current fluctuations resulting from chopper operation. The level of current ripple in the supply capacitors is also influenced by factors such as the internal resistance of the power supply and the length of connecting cables.

Regarding the power supply for VCC_IO, it can be provided either from 5VOUT or from an external source, such as a 3.3V regulator. In applications where the VM (motor voltage) is high, it's advisable to use a different, lower supply voltage for VSA, as explained in Chapter 0, to minimize power dissipation in the internal 5V and 11.5V voltage regulators.

TMC2209 Standard Application Circuit

In the standard application circuit, two sense resistors are utilized to establish the motor coil current, and Chapter 8 provides guidance for selecting the appropriate sense resistors. It is essential to employ low equivalent series resistance (ESR) capacitors for effective power supply filtering. These capacitors should be capable of handling the current fluctuations resulting from the chopper operation. For optimal performance, it is recommended to have a minimum capacitance of 100µF in close proximity to the driver.

The level of current ripple in the supply capacitors is influenced by factors such as the internal resistance of the power supply and the length of the connecting cables. VCC_IO can be powered either from 5VOUT or from an external source, such as a 3.3V regulator.

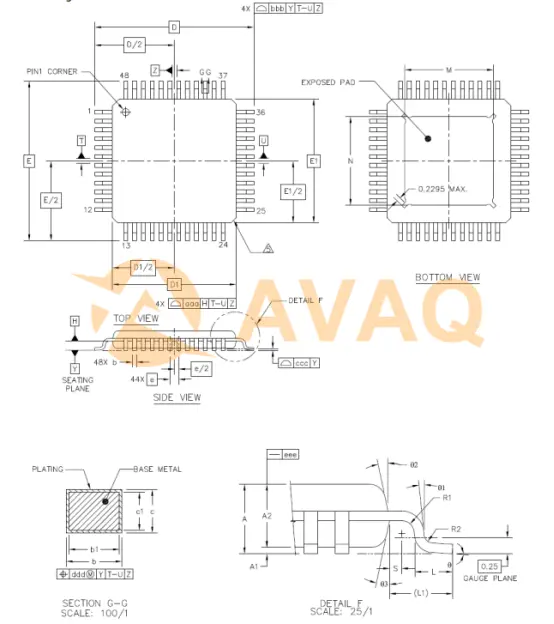

TMC5160 vs TMC2209: Pacakge

TMC5160 Pacakge: TQFP48-EP

TMC2209 Pacakge: QFN28

TMC5160 Vs TMC2209:Pros and Cons

|

Feature |

TMC5160 |

TMC2209 |

|

Pros |

|

|

|

High Power Handling |

Can drive high-power stepper motors (1 to several 10A). |

Suitable for lower to medium-power stepper motors (up to 2.8A peak). |

|

Precision and Smoothness |

Offers advanced control features for precise and smooth operation. |

User-friendly with MicroPlyer™ interpolation for smooth motion. |

|

Quiet Operation |

Noiseless operation with StealthChop2™ and resonance damping. |

Provides silent motor operation with StealthChop2™. |

|

Advanced Control |

Supports SPI and Single Wire UART for advanced control and diagnostics. |

Offers simplicity and ease of use, suitable for entry-level applications. |

|

Encoder Interface |

Includes an encoder interface for precise feedback and position control. |

- |

|

Cons |

|

|

|

Higher Cost |

May be more expensive, which could be a drawback in cost-sensitive applications. |

Cost-effective solution, but not suitable for high-power applications. |

|

Overkill for Low-Power Apps |

Overpowered for applications with lower power requirements. |

- |

|

Limited Advanced Features |

- |

Lacks some advanced features found in higher-end motor drivers. |

|

Simplified Control |

- |

Offers a simplified interface, which may not be suitable for highly advanced control. |

|

Limited Power Handling |

- |

Maximum current rating of up to 2.8A (peak) or 2A RMS. |

|

Energy Efficiency |

- |

Energy-efficient with CoolStep™ current control. |

TMC5160 and TMC2209 Datasheet PDF

Check and download TMC5160 and TMC2209 Datasheet PDF below,

TMC5160 and TMC2209 Manufacturer

The TMC5160 and TMC2209 motor driver ICs are manufactured by Trinamic Motion Control GmbH & Co. KG. Trinamic is a German semiconductor company that specializes in motion control and motor drive technologies, and they produce a range of products for controlling and driving various types of motors, including stepper motors.

Trinamic Motion Control GmbH & Co. KG is a well-known and respected manufacturer in the field of motion control and motor drive solutions. The company is based in Hamburg, Germany, and it has gained a reputation for its innovative and high-quality semiconductor products designed to enhance the performance and efficiency of various motion control applications.

Trinamic's products, such as the TMC5160 and TMC2209 motor driver ICs, have found widespread use in industries ranging from 3D printing and CNC machining to robotics and automation. These ICs are valued for their advanced features, precision, and the ability to deliver silent and efficient motor control, making them popular choices for both hobbyist and industrial applications.

The company's commitment to research and development, as well as its focus on user-friendly interfaces and compact designs, has contributed to its success in providing cost-effective and high-performance solutions for the motion control industry. Trinamic's dedication to continuous innovation and excellence has solidified its position as a key player in the world of motor control and driver technology.

FAQ

FAQ

- Can the TMC5160 and TMC2209 be used interchangeably in the same applications?

- While both drivers are designed for stepper motor control, they have different features and performance capabilities. The choice between them depends on the specific requirements of your application. The TMC5160 is suitable for high-performance applications, while the TMC2209 is a cost-effective choice for simpler applications.

- What is the typical voltage range these drivers can operate with?

- The voltage range may depend on the specific module or implementation, but these drivers can typically operate within a wide voltage range, often from 5V to 35V. It's important to check the datasheets for precise voltage specifications.

- Can the TMC2209 be used in more budget-friendly 3D printers, and if so, what benefits does it offer?

- Yes, the TMC2209 is commonly used in budget-friendly 3D printers due to its cost-effectiveness. It provides smoother and quieter operation compared to some older driver models, contributing to a better user experience.

- Can I upgrade from a TMC2209 to a TMC5160 for better performance?

- Yes, you can upgrade from a TMC2209 to a TMC5160 if your application requires the advanced features and higher performance offered by the TMC5160. However, you may need to make modifications to your control system and have a compatible interface (e.g., SPI).

TMC5160A-TA

Popular Industry Focus

Popular Industry Focus

Related Parts

-

TBD62786APG

Toshiba Semiconductor

Power Switch/Driver 1:1 P-Channel 400mA 18-DIP

-

LTC3586EUFE-3#PBF

Analog Devices, Inc

Handheld/Mobile Devices PMIC 38-QFN (4x6)

-

TBD62304AFWG,EL

Toshiba Semiconductor

Gate Drivers DMOS Transistor Array 7-CH 50V 0.5A

-

TLS850B0TEV33ATMA1

Infineon Technologies Corporation

Linear Voltage Regulator IC Positive Fixed 1 Output 500mA PG-TO252-5

-

LTC3830ES#PBF

Analog Devices, Inc

High Power Step-Down Synchronous DC/DC Controllers for Low Voltage Operation

-

TCK304G,LF

Toshiba Semiconductor

Power Switch ICs - Power Distribution Load Switch IC 3.0A 28V 73mohm

-

LP3910SQX-AN/NOPB

Texas Instruments, Inc

Handheld/Mobile Devices PMIC 48-WQFN (6x6)

-

MIC2145YMM-TR

Microchip Technology, Inc

Boost, Flyback, SEPIC Switching Regulator IC Positive Adjustable 2.4V 1 Output 500mA 8-TSSOP, 8-MSOP (0.118", 3.00mm Width)

-

FAN5660IM

ON Semiconductor, LLC

Switching Voltage Regulators DC/DC

-

VN7003ALHTR

STMicroelectronics, Inc

Single channel 3 mOhm High-side driver with Current Sense analog feedback for automotive applications

-

UCC28C41DGK

Texas Instruments, Inc

Industrial, 20-V, low-power current-mode PWM controller, 7-V/6.6-V UVLO, 50% duty cycle

-

TCK127BG,LF

Toshiba Semiconductor

Power Switch/Driver 1:1 P-Channel 1A 4-WCSPG (0.65x0.65)

-

UC3842AD8TR

Texas Instruments, Inc

Power Supply Controller PWM Controller 8-SOIC

-

LT1961IMS8E#PBF

Analog Devices, Inc

1.5A, 1.25MHz Step-Up Switching Regulator

-

MAX8533EUB+

Analog Devices, Inc

Hot Swap Controller 1 Channel InfiniBand™ 10-uMAX/uSOP

Update Time: Oct 30, 2023 Consumer Electronics

Update Time: Oct 30, 2023 Consumer Electronics