-

Sales personnel submit customer purchase requirements to the warehouse center

-

Warehouse staff will transport materials to the outgoing inspection area and apply for outgoing inspection

-

Quality inspection personnel shall conduct sampling inspection of materials and fill in inspection report after completion of inspection

-

According to the inspection report results, the warehouse personnel will package the materials that have passed the inspection and transport them to the area to be shipped

Testing Items

Professional and trustworthy

-

External Visual Inspection

Through appearance inspection, determine whether the chip is new, whether it is refurbished, whether the pin is tinned, oxidized, etc

-

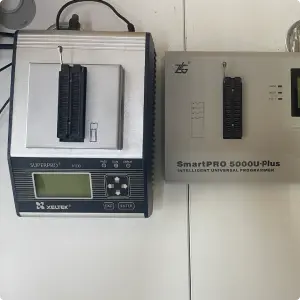

Programming

Test all chips that can support programming

-

Function Testing

It means to carry out various necessary logic or signal state tests under specific working conditions (i.e. normal operating environment of the device) and the normal working state of the device

-

Decapsulation

After etching the package on the surface of the chip, check the inside, verify the authenticity of the chip and analyze the failure

-

Rohs test

(Pb)/(Cd)/(Hg)/(Cr6, +)/(PBBs)/(PBDEs), six kinds of harmful substances content in the homogenous material cannot exceed limit value, which (Cd) is 0.01%, the remaining 0.1%

-

IC authenticity test

Through a variety of ways to identify the ic authenticity, only sell new original

-

Heated Chemical Test

Chemical agents are used to peel the coating from the surface of the chip to verify whether there are abrasion marks, coating, retyping and other problems

-

X-Ray

Mainly check the chip pin frame, wafer size, gold wire binding diagram, ESD damage and holes, customers can provide good products for comparison inspection

-

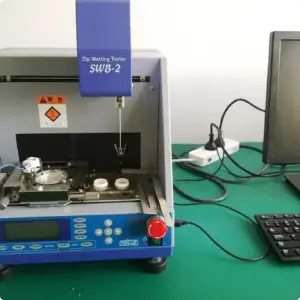

Solderability Test

According to the test standard of solderability test, this test mainly tests whether the tin loading capability of chip pins meets the standard

-

Electrical Test

Use a semiconductor tube characterization chart to check for damage to the chip through open and short circuit tests.

-

Label Detection

The standard inspection is based on the label photo provided by the customer and the original label, the official website information for comparative analysis, so as to identify its authenticity

-

Expectations

Please look forward to

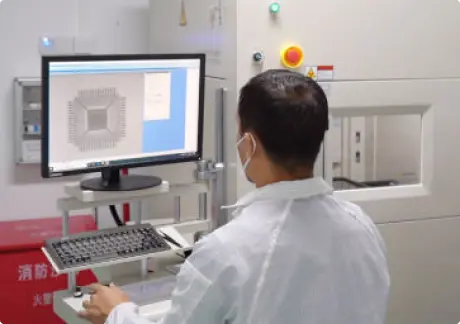

Common Quality Inspection Equipment

More professional & more accurate

A good quality control system cannot be achieved without three elements: a rigorous quality control team, a strict process system, and high-quality quality control equipment

The foundation determines the height

Excellent results cannot be achieved without an excellent process. In order to provide better testing services, we have built from the laboratory environment to the testing equipment to the testing team one by one with care, strictly in accordance with ISO/IEC17025 & ISO9001 standards, and in accordance with the international standard AS6081 to ensure the professionalism and accuracy of the test results.

Our Guarantee

Comprehensive testing programs with strength

-

Professional and excellent technical team

-

Standard management system

-

Extensive testing experience

-

Professional Electronics Engineer

-

Guarantee of product quality

-

Industry focus in multiple areas

Product Comparison

In recent years, due to the shortage of chips in the electronic chips market, resulting in a lot of refurbished materials, counterfeit materials, etc. on the market; in this regard, AVAQ's attitude is firmly opposed, as a company with faith, we are not only responsible for our customers, but also for ourselves, quality and genuine products are our only criteria.

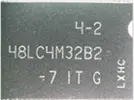

For example:Identify the authenticity of components by wiping the silkscreen through appearance test and acetone test

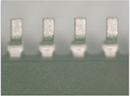

Solderability test to determine the quality of the components and the authenticity of the components by the soldering effect of the pins

Genuine

Before wiping

After wiping

As shown above: true screen printing is still clear after wiping

Before soldering

Success of soldering

As picture shown above:Joint of soldering is smooth and connect with the pins closely

Fake

Before wiping

After wiping

As shown above: fake screen printing is blurred after wiping

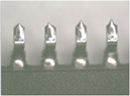

Before soldering

Success of soldering

As picture shown above:Solder failure joint of soldering is not smooth and easy to fall off

OUR CUSTOMERS REVIEW

What Our Customers Are Saying About Us

Our production line was hampered by a shortage of obsolete electronic parts, and AVAQ's inventory helped us overcome this problem in a timely manner; the quality of these parts was up to par, and we will think of AVAQ first the next time we need to purchase electronic chips.

The first time we worked together, we were half-hearted; but from the results, the electronic chips we purchased from AVAQ met our expectations, just as described on the website

AVAQ's quality control is trustworthy, and the parts are brand new and genuine

Original and genuine is the biggest reason why I purchase electronic chips from AVAQ

Great, AVAQ is actually a 365-day warranty service, so I can purchase with peace of mind this time

When you need electronic chips urgently, I confirm to recommend AVAQ, they are not only excellent in quality, but also excellent in service!