Monolithic IC: Overview, Features and Application 2023

Published: Nov 15, 2023

Published: Nov 15, 2023

Contents

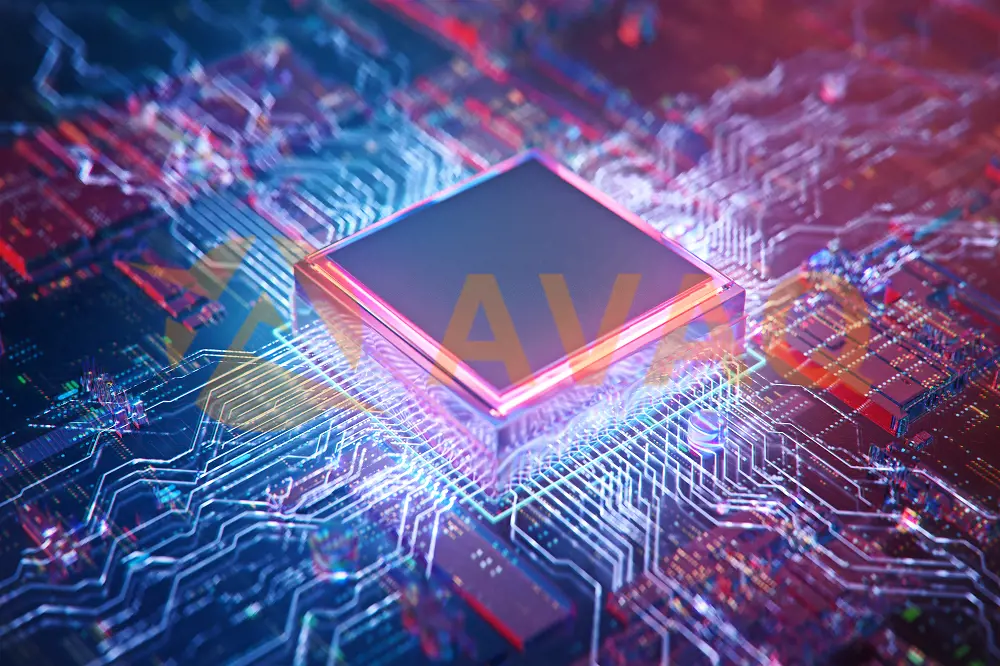

What is a Monolithic IC

A monolithic integrated circuit (IC) is a complete electronic circuit or a group of circuits manufactured on a single piece of silicon, typically around 1.25 mm square (or approximately fifty thousandths of an inch square). This circuit may incorporate fifty or more components like transistors or resistors. The term "monolithic" is derived from the Greek words 'monos' and 'lithos,' meaning single and stone, respectively. It signifies that the circuit is fabricated within a single crystal of semiconductor material. Sometimes referred to as a planar IC, it takes the form of a flat surface.

In the creation of a monolithic IC, a single semiconductor base material, or chip, is used, analogous to an artist using a blank canvas for painting. The initially neutral semiconductor base is selectively processed to create various active devices, such as bipolar junction transistors (BJTs) or field-effect transistors (FETs). Transistors, being three-terminal active devices, provide control over current flow on the main terminals.

Typically, a monolithic IC has a single base semiconductor known as a die. Each die, for example, in an amplifier IC, may contain multiple interconnected transistors forming an electronic circuit that amplifies a low-level signal. The die itself might be as small as 0.04 inches (1 mm) on each side. Miniaturization in electronics allows more than a dozen transistors and passive components like resistors and capacitors to fit in an area less than 0.002 square inches (1 square mm).

However, the die cannot function independently; it needs to be connected to the external world. Small bonding wires, often as fine as two thousandths of an inch and made of malleable metals like gold, are used for this purpose. These wires are fused into the die pads and extend to the outside of an IC package. Ultrasonic bonding is a common method, involving pressing the bonding wire into a die pad with periodic sideward displacement at a rate above 25,000 cycles per second or 25 kilohertz (kHz). This prevents damage to the die from excessive heat, which can occur in other bonding methods. The other end of the bonding wire is fused to the lead frame, which holds the leads accessible from the exterior of a packaged die.

Monolithic integrated circuits are ubiquitous in the manufacturing of integrated circuits and are commonly found in devices like cell phones, computers, and other digital devices. Hybrid ICs may incorporate one or more monolithic integrated circuits on a printed circuit board (PCB) along with resistors, capacitors, inductors, and other active devices like transistors.

Monolithic IC Features

Here are some key features of monolithic ICs:

Compact Size: Monolithic ICs are known for their small physical size. The entire circuit, including various components such as transistors, resistors, and capacitors, is fabricated on a single piece of semiconductor material, allowing for high component density and miniaturization.

Low Power Consumption: The integration of components on a single chip often results in improved power efficiency. Monolithic ICs are designed to perform specific functions with minimal power consumption, making them suitable for battery-powered devices and energy-efficient applications.

High Reliability: The manufacturing process for monolithic ICs involves precise and controlled conditions, leading to consistent and reliable performance. The integration of components on a single chip also reduces the chances of component failures due to external factors.

Improved Performance: Monolithic ICs can achieve high levels of performance due to the close proximity of components on the chip. This proximity reduces signal travel distances, minimizing parasitic capacitance and inductance, and improving the overall speed and efficiency of the circuit.

Cost-Effectiveness: The mass production of monolithic ICs can lead to cost savings. The ability to manufacture large quantities of identical circuits on a single wafer contributes to economies of scale, making these ICs cost-effective for a wide range of applications.

Ease of Integration: Monolithic ICs can be easily integrated into larger electronic systems. Their compact size and standardized packaging make them compatible with various assembly and integration processes on printed circuit boards (PCBs).

Diverse Applications: Monolithic ICs find applications in a wide range of electronic devices, including microprocessors, memory chips, amplifiers, oscillators, and more. Their versatility and ability to perform complex functions make them suitable for diverse industries.

Planar Structure: The planar structure of monolithic ICs, often referred to as planar technology, contributes to their flat and compact design. This structure simplifies the fabrication process and allows for precise control over the placement of components on the semiconductor material.

Scalability: Advances in semiconductor technology have enabled the continuous scaling down of components on monolithic ICs. This scalability allows for the integration of more components, increased functionality, and improved performance over time.

Digital and Analog Functionality: Monolithic ICs can be designed to perform both digital and analog functions on the same chip. This capability is essential for devices that require both signal processing and control functions.

Applications of Monolithic ICs

Monolithic integrated circuits (ICs) have become integral components in a diverse array of electronic applications.

Consumer Electronics:

- Televisions: Monolithic ICs contribute to the control circuits and signal processing units, enhancing the performance and functionality of modern TVs.

- Audio Systems: Monolithic ICs play a key role in amplifying and processing audio signals in stereo systems, speakers, and headphones.

- Mobile Phones: Monolithic ICs are essential for mobile phone functionality, including power management, signal processing, and communication subsystems.

Medical Devices:

- Pacemakers and Defibrillators: Monolithic ICs are crucial in the control circuits of cardiac devices, ensuring precise and reliable operation.

- Medical Imaging Equipment: Monolithic ICs contribute to signal processing and control systems in devices like MRI and CT scanners, enhancing diagnostic capabilities.

Automotive Electronics:

- Engine Control Units (ECUs): Monolithic ICs are used for precise control of engine functions, optimizing fuel efficiency and emissions.

- Airbag Control Units: Monolithic ICs contribute to safety systems by managing the deployment of airbags in response to various conditions.

- Infotainment Systems: Monolithic ICs play a role in the signal processing and control circuits of in-car entertainment systems.

Industrial Automation:

- Programmable Logic Controllers (PLCs): Monolithic ICs are fundamental to the control and processing units of PLCs, enabling automation in manufacturing processes.

- Motor Control Systems: Monolithic ICs contribute to efficient motor control, enhancing the precision and reliability of industrial machinery.

- Sensors: Monolithic ICs are used in sensor interfaces, providing the necessary signal conditioning and processing for accurate data acquisition.

Aerospace and Defense:

- Satellite Communication Systems: Monolithic ICs are essential in communication subsystems of satellites, ensuring reliable transmission of data.

- Radar Systems: Monolithic ICs contribute to signal processing and control circuits in radar systems, enabling accurate detection and tracking.

- Missile Guidance Systems: Monolithic ICs play a critical role in guidance and control units, ensuring precision in missile trajectories.

Advantages and Disadvantages of Monolithic IC

Advantages of Monolithic ICs:

- Size and Weight: Monolithic ICs are compact and lightweight, allowing for the miniaturization of electronic devices and systems.

- Power Efficiency: The integration of components on a single chip often results in lower power consumption, making monolithic ICs energy-efficient.

- Reliability: The manufacturing process of monolithic ICs is highly controlled, leading to consistent and reliable performance, with fewer points of failure compared to discrete components.

- Cost-Effective Mass Production: Large-scale production of identical circuits on a single wafer leads to economies of scale, making monolithic ICs cost-effective.

- High Performance: The close proximity of components on the chip reduces signal travel distances, minimizing parasitic effects and enhancing the overall speed and performance of the circuit.

- Ease of Integration: Monolithic ICs are easily integrated into larger electronic systems, simplifying the design and assembly processes on printed circuit boards (PCBs).

- Versatility: Monolithic ICs can be designed to perform a wide range of functions, from digital processing to analog signal conditioning, making them versatile for diverse applications.

- Scalability: Advances in semiconductor technology allow for the continuous scaling down of components, enabling increased functionality and performance.

- Digital and Analog Integration: Monolithic ICs can seamlessly integrate digital and analog functions on the same chip, providing flexibility in designing complex systems.

Disadvantages of Monolithic ICs:

- Complex Manufacturing Process: The fabrication of monolithic ICs involves intricate processes, including photolithography and doping, making manufacturing complex and requiring specialized facilities.

- High Initial Design Costs: Designing a monolithic IC can be costly due to the need for specialized knowledge, tools, and software, especially for complex applications.

- Limited Repairability: If a component on a monolithic IC fails, the entire IC may need replacement since individual components are not easily replaceable.

- Limited Customization: Once a monolithic IC is fabricated, changes to its design can be challenging, limiting the ability to customize or modify the circuit for specific applications.

- Heat Dissipation: High component density on the chip can lead to localized heating, requiring additional measures such as heat sinks or cooling systems.

- Obsolete Technology: As technology advances, older monolithic ICs may become obsolete, leading to challenges in maintaining and repairing older electronic systems.

- Single Point of Failure: Since all components are integrated into a single chip, a failure in one part of the IC can impact the entire functionality, potentially leading to a complete system failure.

- Sensitivity to Environmental Factors: Monolithic ICs can be sensitive to environmental factors such as temperature and humidity, which may affect their performance.

Difference between Monolithic Integrated Circuits and Hybrid Integrated Circuits

I. Monolithic Integrated Circuit

Monolithic integrated circuits (ICs) are circuits in which multiple electronic components (e.g., transistors, capacitors, resistors, etc.) are integrated on a single silicon chip. Compared with traditional discrete components, monolithic integrated circuits have obvious advantages in terms of usage, size, power consumption, and reliability.

Monolithic integrated circuits can be divided into two types: digital integrated circuits and analog integrated circuits. Digital integrated circuits are mainly used for digital systems, which are widely used in the fields of computers, communications, control, etc., while analog integrated circuits are used for analog signal processing, which have many applications in the fields of audio, video, and electricity.

Ⅱ Hybrid Integrated Circuits

Hybrid integrated circuits (HICs) are circuits that integrate different types of circuit components, such as analog circuits, digital circuits, RF circuits, etc. together to form a single chip. Hybrid integrated circuits have the effect of both digital circuits and analog circuits, and can process both digital and analog signals.

Compared to monolithic integrated circuits, hybrid integrated circuits have a higher degree of integration and a wider range of applications. Because hybrid integrated circuits can handle both analog and digital signals, they can be used in communication, radar, radio, audio and other fields.

Ⅲ Differences and Applications

The biggest difference between monolithic integrated circuits and hybrid integrated circuits lies in the different types of signals they handle. Monolithic integrated circuits handle digital signals, while hybrid integrated circuits can handle both digital and analog signals.

In addition, monolithic integrated circuits are single component integrated circuits that are less integrated and less difficult to manufacture than hybrid integrated circuits. Hybrid integrated circuits, on the other hand, utilize different types of components and are more complex and advanced in both manufacturing and design.

In terms of applications, monolithic integrated circuits are mainly used in digital electronic devices, such as computers, cell phones, cameras, controllers, etc.; whereas hybrid integrated circuits are mainly used in communication devices, radar systems, audio processing, power amplifiers, etc.

In short, both monolithic integrated circuits and hybrid integrated circuits are very important types of integrated circuits and have irreplaceable roles in their respective fields of application. Difference between Chip IC and Hybrid IC.

FAQ

FAQ

- Can monolithic ICs be customized for specific applications?

- Yes, monolithic ICs can be customized for specific applications during the design phase. Customization allows designers to optimize the circuit for particular functionalities or performance requirements.

- How does the performance of monolithic ICs compare to other types of ICs?

- Monolithic ICs generally offer high performance due to the integration of components on a single chip, reducing parasitic effects and improving speed. This makes them suitable for a broad range of applications.

- Are monolithic ICs used in modern electronic devices?

- Yes, monolithic ICs are extensively used in modern electronic devices. They form the backbone of microprocessors, memory chips, and a wide range of specialized circuits used in computers, smartphones, automotive electronics, and more.

- What is the significance of monolithic ICs in the history of electronics?

- The development of monolithic ICs revolutionized the electronics industry by enabling the creation of compact, reliable, and cost-effective electronic devices. This innovation marked a shift from discrete component-based circuits to integrated solutions.

- Can monolithic ICs include both analog and digital components?

- Yes, many monolithic ICs are designed to include both analog and digital components on the same chip. These are often referred to as mixed-signal ICs.

pt2399

Popular Industry Focus

Popular Industry Focus

Hot Products

-

MCP3208-BI/SL

Microchip Technology, Inc

12-Bit, 100kSPS, 8-Channel ADC.

-

USB3503-I/ML

Microchip Technology, Inc

USB Hub Controller USB 2.0 USB Interface 32-SQFN (5x5)

-

AT27LV520-70XC

Microchip Technology, Inc

Microchip Technology

-

PIC16C55A-04/P

Microchip Technology, Inc

8-bit Microcontrollers - MCU .75KB 24 RAM 20 I/O 4MHz PDIP-28

-

MCP41100-E/SN

Microchip Technology, Inc

8-Bit Single Digital POT with SPI.

-

MCP4161T-103E/SN

Microchip Technology, Inc

Digital Potentiometer 10k Ohm 1 Circuit 257 Taps SPI Interface 8-SOIC

Related Parts

-

TA8304F

Toshiba Semiconductor

Bipolar Linear Integrated Circuit Silicon Monolithic 16-Pin SSOP

-

NEO-M8P-0-11

U-BLOX AG

NEO-M8P RF Receiver BeiDou, GLONASS, GNSS, GPS 1.575GHz -160dBm

-

RKV501KJ#R1

Renesas Technology Corp

Varactors Single 35 V Surface Mount 2-UFP

-

W83C553F

Nuvoton Technology Corporation

I/O Controller Phase Controller 208-Pin PQFP

-

AT97SC3204-X4A12ABFB

Microchip Technology, Inc

Microchip Technology

-

AT97SC3205T-X3A17AAB

Microchip Technology, Inc

Microchip Technology

-

ANX6210

Analogix Semiconductor

Multimedia Converter Display Port to VGA 2560x1600Pixels 5.4Gbps

-

AD9840JST

Analog Devices, Inc

AFE Video 1 ADC 10bit 3V 48-Pin LQFP

-

BCM47758KUB1G

Broadcom Corporation

OEMs, CMs ONLY (NO BROKERS)

-

NH82801DBM SL7VK

Intel Corp

I/O Controller 421-Pin BGA

-

FDC37B807

Microchip Technology, Inc

Controllers, PC98/99 Compliant Enhanced Super I/P Controller

-

AD1896YRS

Analog Devices, Inc

Audio Sample Rate Converter 2 Channel 28-SSOP

-

ANX1122

Analogix Semiconductor

Multimedia Converter 2 Lane Display Port to LVDS 2560x1600Pixels 5.4Gbps

-

LSI53C1010-33

Broadcom Corporation

PCI-Ultra 160 SCSI Controller Dual-CH PCI/Flash Memory

-

Z84C4206CMB

Zilog, Inc

I/O Controller 0.015A

Update Time: Nov 20, 2023 Consumer Electronics

Update Time: Nov 20, 2023 Consumer Electronics