Transformer vs Converter: What are Differences

Published: Nov 09, 2023

Published: Nov 09, 2023

Contents

What is Transformer

#1 Definition

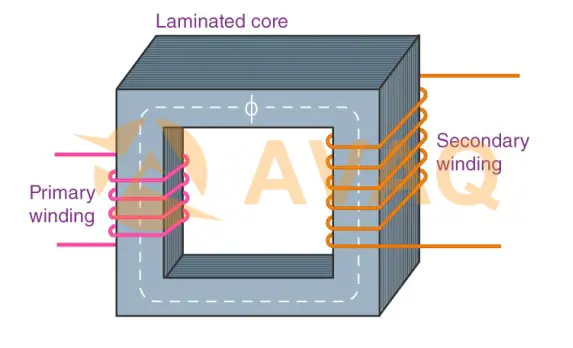

Transformer is a device that utilizes the principle of electromagnetic induction to change the AC voltage. It mainly consists of two coils and an iron core, and the transformation of AC voltage can be realized through the electromagnetic interaction between the coils. Specifically, when an alternating current flows through one of the coils, it generates a magnetic field in the iron core, which in turn generates an electromotive force in the other coil, thus realizing the effect of voltage transformation. Transformers are widely used in power distribution systems to change the voltage level in order to transfer power between different electrical devices.

#2 Components

The constituent parts of a transformer include the body (core, windings, insulation, fuse), transformer oil, oil tank and cooling device, voltage regulator, protection device (moisture absorber, safety airway, gas relay, oil storage cabinet and temperature measurement device, etc.), and outlet bushing. Specific composition and function:

(1) Iron core. Iron core is the main magnetic circuit part in the transformer. Usually high silicon content, the thickness of 0.35mm, 0.3mm, 0.27mm, coated with insulating varnish on the surface of the hot-rolled or cold-rolled silicon steel sheet stacked into. Iron core is divided into iron core column and cross piece of two parts, iron core column sets of windings; cross piece is used to close the magnetic circuit.

(2) Winding. Winding is the circuit part of the transformer, it is with double wire wrapped insulated flat wire or enameled round wire winding. The basic principle of the transformer is the principle of electromagnetic induction, single-phase double winding transformer as an example to illustrate the basic principle of its work: when the primary side of the winding plus voltage U1, the flow of current I1, in the core of the alternating flux O1, these fluxes are called the main flux, under its action, the two sides of the windings were induced potential, and finally led to the transformer regulator.

#3 Principle of operation

Transformer is the use of the principle of electromagnetic induction to change the alternating current voltage device, the main components are the primary coil, secondary coil and core (core).

In electrical equipment and radio circuits, it is often used to raise and lower the voltage, matching impedance, safety isolation and so on. In a generator, an electric potential is induced in the coil whether the coil moves through a magnetic field or the magnetic field moves through a fixed coil.

In both cases, the value of the magnetic flux remains the same, but the amount of flux intersecting the coil changes, which is the principle of mutual induction. A transformer is a device that utilizes electromagnetic induction to transform voltage, current and impedance.

#4 Classification

(1) Power Transformer

At present, the representative products have been operating in the system include: 1150KV, 1200MV-A, 735 ~ 765KV, 800MV-A, 400 ~ 500KV, 3-phase 750MV-A or single-phase 550MV-A, 220KV, 3-phase 1300MV-A power transformers; DC transmission ± 500KV, 400MV-A converter transformer. Power transformers are mainly oil-immersed, the product structure for the core type and shell type two categories.

Core-type production accounted for 95%, shell-type accounted for only 5%. Core-type and shell-type mutual and no overwhelming advantages, just core-type process is relatively simple, and therefore is used by the majority of enterprises; and shell-type structure and process are more complex, only the traditional factory. Shell type is especially suitable for high voltage, large capacity, its insulation, mechanical and heat dissipation have advantages and suitable for mountainous hydropower station transportation.

(2) Distribution Transformer

Foreign distribution transformer capacity can reach 2500KV-A, round and oval core form. The vast majority of round, oval due to M0 (core column spacing) is small, so the material can be reduced, its corresponding coil is oval. Low-voltage coils are wire-wound or foil type, and there are oil tanks with heat sinks (a few) and corrugated ones (most).

(3) Dry-type transformer

Recently, dry-type transformer in China has been rapid development, in Beijing, Shanghai and Shenzhen and other large cities, dry-type transformer has accounted for 50%, and in other large and medium-sized cities has also accounted for 20%. There are four kinds of structure of dry transformer: epoxy resin casting, adding filler casting, winding and impregnation.

At present, Europe and the United States are widely used open ventilated H-class dry-type transformers, is in the impregnated on the basis of absorbing the characteristics of the structure of the winding package and the use of Nomex paper after the development of a new type of H-class dry-type transformers, due to the high price in our country has not yet been popularized.

At present, the domestic through the short-circuit test capacity of the largest dry-type distribution transformer is 2500KV-A, 10/0.4KV; through the short-circuit test capacity of the largest dry-type power transformer is 16000KV-A, 35/10KV.

(4) Amorphous alloy transformer

Amorphous alloy transformer, although poor short-circuit resistance, noise, but energy-saving, so the future development prospects are promising. At present, China's largest amorphous alloy transformer core production enterprises with 3000 ~ 4000t annual production capacity of the core, the core and transformer production technology is not a restriction on the promotion of amorphous alloy core gold transformer is a critical factor, amorphous alloy strip breakthroughs can lead to a qualitative leap in products.

(5) Coil core transformer

At present, the volume of core transformer production is mainly concentrated in the 10KV level, capacity is generally less than 800KV-A, but also trial production of 1600KV-A, but the power sector procurement to 315KV-A below the capacity of the majority, suitable for agricultural networks.

China's existing coil-core transformer production plant more than 200, with a certain scale accounted for 20%. China's strong volume core transformer production capacity of about 16 million KV-A, but the actual output is low.

#5 Role

Role: voltage conversion, current conversion, impedance conversion, isolation, voltage stabilization (magnetic saturation transformer), etc.

- (1) Power transformer: used for transmission and distribution system voltage rise and fall.

- (2) Instrumentation transformers: such as voltage transformers, current transformers, for measuring instruments and relay protection devices.

- (3) Test transformer: it can produce high voltage, high voltage test of electrical equipment.

- (4) Special transformers: such as furnace transformers, rectifier transformers, adjustment transformers, capacitor transformers, phase shifter transformers and so on.

In different environments, transformers are used for different purposes, such as:

1. To carry out long-distance transmission when the voltage can be raised to reduce the power loss on the line.

2. Reducing the voltage when reaching the area of use can meet the power needs of different users.

3. Impedance matching when using transformers can play a role in changing the impedance of the connection.

4. The use of isolation transformers can isolate the two phases of electricity to prevent electrocution accidents.

What is Converter

#1 Definition of Converter

A converter is an electrical device used to convert electrical energy from one form to another. Similar to a converter, a converter is required to convert power from one form to another, but they are usually designed to perform specific power conversion tasks. For example, DC-DC converters are used to convert DC voltage from one level to another to meet system requirements. Another example is an AC to DC converter, which converts an AC voltage to a DC voltage and is often used in electronic devices.

DC-DC Converter

A DC-DC converter is an electronic circuit that converts a DC voltage or current level to another DC voltage or current level. In most cases, devices use only one power source.

If different sub-circuits require different voltages to function properly, only then the input voltage needs to be converted to a lower or higher level, and this can be done with a DC-DC converter.

In addition to converting the voltage, DC-DC converters can be used to stabilize the voltage without letting it drop or rise too much. For example, one of the uses of an automotive DC-DC converter is to regulate voltage fluctuations in an automotive alternator.

#2 Common DC-DC Converter

1. Linear DC-DC Converter

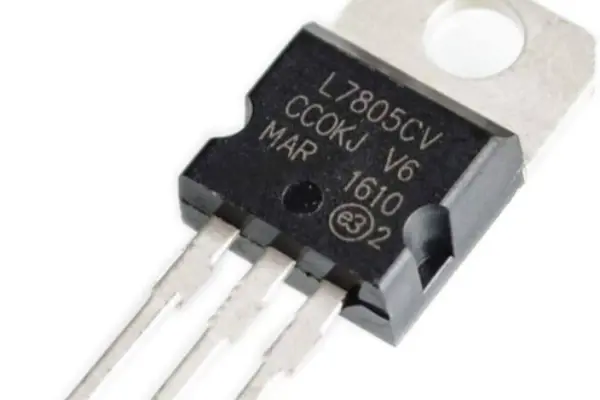

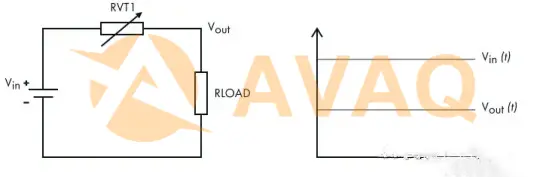

Linear converter reduces the output voltage through a resistive load where the input and output are connected to a transistor. The input voltage is reduced by the voltage across the transistor, which results in a drop in the output voltage.

Linear DC-DC converter is the simplest type of converter where the voltage is reduced by a transistor placed between the input and output.

Linear DC-DC converters have simple and cheap circuits but they have many disadvantages. It can only be used to reduce the voltage and in addition, the efficiency decreases as the difference between the input and output voltage increases.

On the other hand, unused power is dissipated as heat and can easily overheat if the difference between the input and output voltages is large.

Linear DC-DC is used in low power devices and nodes that require high quality output voltages and low output voltage ripple or in devices that are sensitive to electromagnetic interference.

Linear converters are typically used in audio and video electronics, communications equipment, medical and measurement equipment.

2. Switching DC-DC converter

Switching converters use a switching element to charge a storage capacitor with an electrical pulse, and then the voltage is smoothed through the capacitor and transferred to the load, with the output voltage level defined by the duty cycle of the switching element.

A switched DC-DC converter consists of a power switch, conductor coil, diode and storage capacitor. The number of components and their arrangement affects the operation of the converter.

The input voltage is applied in pulses, but the capacitors smooth it out. Switching converters are more efficient compared to linear converters and can reach 85-90%.

Because of the higher efficiency, they also don't generate as much heat, can be used to reduce and increase the output voltage, generate more electromagnetic noise and require more components, and can be more expensive.

Practical examples of DC converter applications:

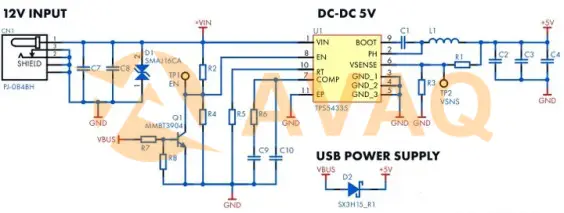

Below is a real-world project where multiple sub-circuits in a device with multiple radio transmitters need to be powered.

The sub-circuits require 5V and the input voltage is 12V. The maximum current is up to 2A. In this case it is not practical to use a linear converter because more than half of the energy is dissipated as heat (up to 14W full power).

Installing a cooling radiator is also not a good option because the enclosure is too small (10x10x1 cm). Instead, use the TPS54335 converter.

The switching converter avoids generating too much heat when the difference between the input and output voltages required by the subcircuits is too large.

3. Non-isolated and isolated DC-DC converter

Non-isolated DC-DC designs are characterized by a direct connection between the input and output circuits to each other (i.e., having a single circuit) and can be used in low-power devices compared to isolated models. Examples include communications, computers, automotive and other industries.

Isolated converters, where the inputs and outputs are separated from each other, usually use a transformer that prevents DC flow between the 2 circuits.

Typically the primary and secondary are separated and are widely used in high voltage DC-DC converters. In addition, this design allows you to disconnect the ground loop, which can protect sensitive circuits from noise.

It can be used for programmable logic controllers, industrial automation, and power supplies for IGBT drivers.

Isolated Converter Circuit Example

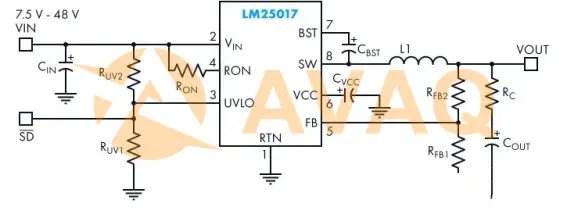

For example, in the following example, an isolated converter is necessary because the device operates in a humid environment. Here, the LM25017 fly-buck regulator is used

The LM25017 fly-buck regulator is ideal for systems where there is a risk of electric shock.

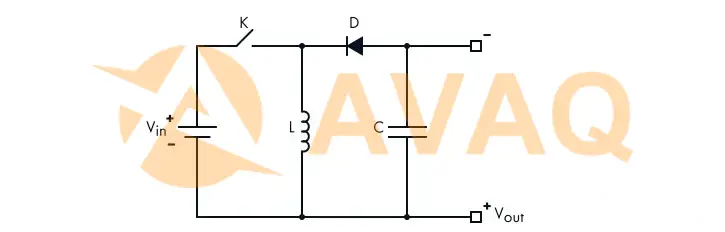

4. Buck DC-DC converter

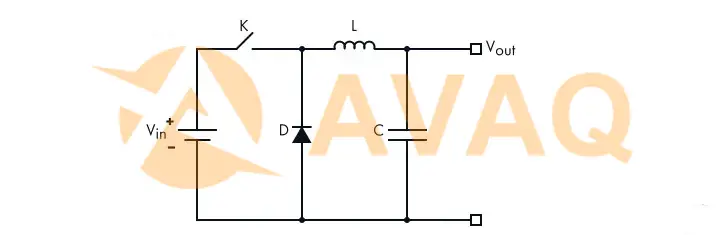

Buck converter that produces a lower output voltage compared to the input.

In a simple buck converter, the switching element (K) quickly turns the power supply on and off. The output voltage looks like a series of square waves. When the switch opens, the coil (L) and capacitor (C) accumulate energy.

The capacitor smoothes these waves into a DC voltage. When the voltage reaches the desired level, the switching element closes and the diode (D) conducts. The self-inductive electromotive force causes current to stay through the diode and the energy accumulated in the coil charges the load.

A simple buck converter schematic is shown below.

Buck converters are used in many areas, including battery chargers, multimedia players, game consoles, monitors, and televisions.

5. Boost DC-DC converter

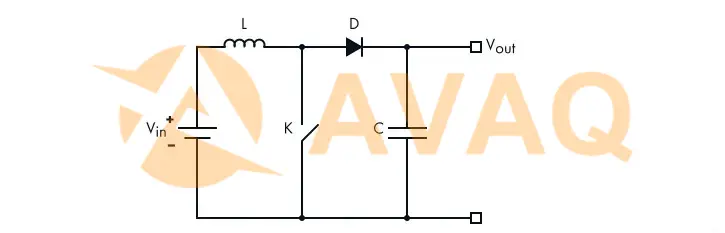

A boost DC-DC can produce a voltage higher than the input voltage. In a typical boost converter, an induction coil receives almost all of the current, and a closed diode does not allow the current to charge the capacitor and load.

Because of the higher current, the coil can accumulate more magnetic energy compared to the buck schematic, and when the voltage drops to a certain point, the power button closes while the diode conducts.

The input voltage increases the energy stored in the coil, in which case the output voltage of the boost DC-DC converter is higher than the input voltage.

As shown above, a boost DC-DC converter has the same components as a buck converter, switching elements, conductor coils, diodes and capacitors, but arranged differently.

Boost converters are commonly used in hybrid vehicles, lighting systems that use energy efficient lamps, portable lighting equipment.

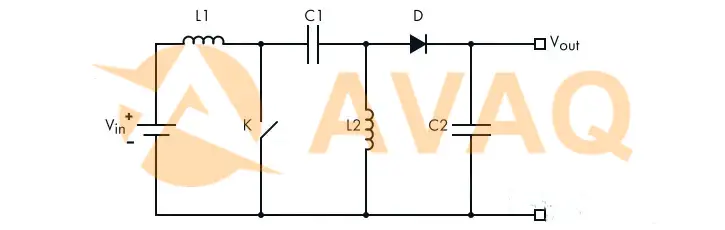

6. Buck-bosst DC-DC converter

A buck-bosst DC-DC converter can increase and decrease the input voltage to produce a higher or lower output level. They are often used when a wide input voltage range needs to be handled.

In this case, the converter uses 2 conductors and 2 capacitors to raise and lower the voltage.

A buck-bosst DC-DC converter is typically used in devices powered by lithium-ion batteries. Normally the converter reduces the voltage to the desired level. But as the battery voltage drops over time it will start to rise.

7. Inverted DC-DC converter

The main function of an inverting DC-DC converter is to reverse the polarity of the output voltage. The output level can be higher or lower than the input level. When a device requires dual power supplies (e.g. operational amplifiers)

#2 Converter Characteristics

When selecting a DC-DC converter, you need to pay attention to the following characteristics and parameters, the most important ones are as follows:

1. Input Voltage

The input voltage is defined by the power supply used, and different power supplies provide different input voltages. When designing, it is important to ensure that the DC-DC converter can withstand these voltages.

2. The output voltage

DC-DC converter can produce a fixed or adjustable output voltage, can be from the minimum to the maximum value, in general, the choice of model is determined by the voltage range required by the load.

3. Output Current

The output current defines the electrical power that the converter can provide.

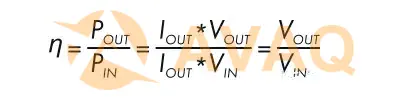

4. Efficiency

Efficiency is the percentage of input power transferred to the output and can be used in the following formula:

This parameter is crucial if, for example, the efficiency of a DC-DC converter varies greatly. For example: if the device is powered by a battery, the efficiency defines how long the device can work before the battery has to be replaced.

In some cases, however, efficiency is not as important. The energy lost during conversion is then dissipated in the form of heat.

5. Temperature

Since the extra energy is converted into heat, overheating can become a serious problem, and this is when additional thermal protection must be used.

6. Size and installation

DC-DC converters are available in a wide range of package types, and if they need to be mounted into a PCB, there are a variety of mounting options available, but size should also be considered.

Difference between a Voltage Converter and a Voltage Transformer(Video)

This video will help you decide if you need a voltage converter for your device or a voltage transformer.

Transformer vs Converter: What are Differences

The main differences are their functions and fields of application, as well as their basic principles:

Role and field of application

Transformers are mainly used to change the level of voltage in AC circuits and are commonly used in the field of power transmission and distribution, as well as to convert current from high-voltage transmission lines to low-voltage currents suitable for household and industrial equipment.

A converter is a more general term that can be used to convert energy, voltage, signals, or data from one form to another and can be used in power management, signal processing, communications, and a wide variety of electronic devices.

Basic Principles

The working principle of transformer is based on electromagnetic induction in which a magnetic field changes the voltage through the mutual inductance of coils. It does not involve conversion of voltage to current, but only changes the voltage level.

The working principle of a converter varies according to its type. For example, converters in power electronics (e.g., inverters and rectifiers) involve the conversion of current and voltage, while data converters (e.g., ADCs and DACs) involve the conversion of analog and digital signals.

|

Feature |

Transformer |

Converter |

|

Definition |

Used to change the voltage level in an AC electrical circuit. |

Used to convert one form of energy, voltage, signal, or data into another form. |

|

Components |

Primarily composed of primary and secondary coils wound around a common magnetic core. |

Composed of various components depending on the type, including electronic elements, switches, sensors, and control circuits. |

|

Working Principle |

Operates based on electromagnetic induction by changing voltage through mutual inductance. |

The working principle varies by type and may involve the conversion of current, voltage, or data. |

|

Purpose |

Mainly used for voltage stepping (up or down), in power transmission, and distribution. |

Used for power management, signal processing, communication, and various other applications. |

|

Popular Models |

- ABB Power Transformers - Siemens Transformers - Toshiba Power Transformers - Schneider Electric Electronic Transformers |

- DC-AC Inverters - Analog-to-Digital Converters (ADC) - Digital-to-Analog Converters (DAC) - Rectifiers |

FAQ

FAQ

- Can a transformer convert DC to AC or vice versa?

- No, a traditional transformer works with alternating current (AC) only. It relies on the changing magnetic field associated with AC to induce a voltage in the secondary winding. To convert DC to AC, an inverter, which is a type of converter, is used.

- What is the difference between a transformer and a converter?

- A transformer primarily changes the voltage level of AC power, whereas a converter changes the form of electrical energy. Converters can convert AC to DC or DC to AC and may also change voltage levels.

- Are transformers and converters used in renewable energy systems?

- Yes, transformers are used in renewable energy systems to step up or step down voltages in power distribution. Converters are used to interface renewable energy sources, like solar panels or wind turbines, with the electrical grid.

- What is the efficiency of transformers and converters?

- The efficiency of transformers and converters varies depending on the type and design. Modern transformers and converters are designed with high efficiency to minimize energy losses during the conversion process.

- Are transformers and converters used in everyday electronics?

- Yes, both transformers and converters are integral components in various electronic devices. Transformers are commonly found in power supplies and electrical distribution systems, while converters are used in devices like chargers, power adapters, and inverters for solar power systems.

DCP020515DU In Stock: 7422

Popular Industry Focus

Popular Industry Focus

Hot Products

-

MPY634KU/1KE4

Texas Instruments, Inc

Analog Multiplier 4-Quadrant 16-SOIC

-

TPS2060DRBT

Texas Instruments, Inc

2-ch, 1.5A loading, 2.7-5.5V, 70mΩ USB power switch, active-low, reverse blocking

-

TS3USBCA420RSVR

Texas Instruments, Inc

USB Type-C SBU Multiplexer

-

LM2907M-8

Texas Instruments, Inc

Frequency to Voltage Converter IC 10 kHz ±0.3% 8-SOIC

-

CD4046BPW

Texas Instruments, Inc

CMOS Micropower Phase-Locked Loop

-

LMV221SDX

Texas Instruments, Inc

Special Purpose Amplifiers

Related Parts

-

TIM 2-0919

TRACO Electronic AG

Isolated DC/DC Converters - Through Hole 4.5-12Vin 9V 222mA 2W DIP-16 Iso Med

-

PYBJ3-D5-S12-OM

CUI Inc

Module DC-DC 5VIN 1-OUT 12V 0.25A 3W 6-Pin SMD Module Tray

-

THM 30-2421

TRACO Electronic AG

Module DC-DC 24VIN 2-OUT 5V/-5V 3A/3A 30W 5-Pin

-

R-78W9.0-0.5

RECOM Power GmbH

Non-Isolated DC/DC Converters 11-32Vin 9V 0.5A SIP WIRED

-

MYMGK1R820FRSR-H

Murata Manufacturing Co, Ltd

Module DC-DC 5VIN 1-OUT 0.7V to 1.8V 20A 36W 37-Pin SMD Module T/R

-

DCP010512BP-U

Texas Instruments, Inc

Miniature, 1W Isolated Unregulated DC/DC Converters

-

PTH05010WAZ

Texas Instruments, Inc

Non-Isolated PoL Module DC DC Converter 1 Output 0.8 ~ 3.6V 15A 4.5V - 5.5V Input

-

TMR 6-4811WI

TRACO Electronic AG

Module DC-DC 48VIN 1-OUT 5V 1.2A 6W 7-Pin SIP Module

-

TMDC 40-2412

TRACO Electronic AG

Module DC-DC 24VIN 1-OUT 12V 3.33A 40W 8-Pin

-

TMR 6-1223

TRACO Electronic AG

Module DC-DC 12VIN 2-OUT 15V/-15V 0.2A 6W 7-Pin SIP Module

-

UCC12050DVE

Texas Instruments, Inc

500-mW, high-efficiency, 5-kVRMS isolated DC/DC converter

-

XCL219B123FR-G

TOREX

Switching Voltage Regulators 1A Indct / Stp Dwn Micro DCDC Converter

-

TPSM53602RDAR

TEXAS INSTRUMENTS INC

36-V, 2-A step-down power module in small 5.5 x 5 x 4-mm Enhanced HotRod™ QFN with simple footprint

-

OBQ05SC1224

eta-usa

Isolated DC/DC Converters - Through Hole 3W 8-32V TO 5V .5A

Update Time: Nov 13, 2023 Consumer Electronics

Update Time: Nov 13, 2023 Consumer Electronics