Intelligent Camera Module Adhesive Solutions for Consumer Electronics

Published: Apr 28, 2023

Consumer Electronics

Share:

Published: Apr 28, 2023

Consumer Electronics

Share:

The number of camera modules used in consumer electronics devices continues to grow rapidly as electronic devices become more mobile and wearable. Market estimates forecast the global market for CCMs (compact camera modules) to be $31.5 billion in 2020, growing to $44.6 billion by 2024.

A camera module contains many different components integrated into a single unit. Due to space constraints, they can only be assembled together with adhesives. These components are made of many different materials and therefore require different adhesives to bond them. Depending on the specific bonding application, each adhesive has very specific performance targets.

Thanks to our outstanding innovation and advanced technology in the field of electronic adhesives, YASUDA's material scientists have developed and fully supplied adhesive solutions for camera modules for smart consumer electronics, including specialized adhesives for each component, adhesive bonding and curing technology. YASUDA's adhesives offer outstanding versatility to bond to many different materials, have high tensile strength, and withstand harsh environments.

I. Bracket Adhesives

Characteristics

UV curing

Shaded area cures at low temperatures.

Good adhesion to resin and LCP surfaces

Short dispensing cycle time for automatic integration

Low outgassing and low shrinkage

Good temperature stability and resistance to climate change

II. Infrared Filter Adhesives

Infrared filter lenses help remove infrared wavelengths of sunlight, filter diffraction, protect image sensors and prevent images from turning red. The lenses are fixed to the frame with an adhesive. Therefore, the adhesive needs to filter out more than 99% of the infrared radiation.

Features

Optimized camera modulus to ensure drop test reliability

Excellent adhesion to IR filters of various plastic and ceramic materials

Optimized flow characteristics and viscosity for easy adjustment of dispensing pins

Low-temperature cure helps avoid damage to optics and coatings.

Adhesive colors from clear to black, adjustable to customer requirements

Good temperature stability and resistance to climate change

Low outgassing

III. Camera Module Voice Coil Motor (VCM) Special Adhesive

Today, millions of smartphone cameras are equipped with autofocus (AF) and OIS optical stabilization technology based on the VCM platform. YASUDA's adhesives can hold parts extremely quickly and can cure blurred areas. This is a big advantage because VCM modules have many very small details and have surfaces that are as difficult to bond as LCP or PC.

Features

UV curing

Low-temperature curing

Very low outgassing without damage to lenses, filters, or sensors

Excellent bond strength on substrates and metals used in LCP and PC, etc.

Fast curing and high performance

Drop test resistance

Solvent-free composition

IV. Retainer Replacement

Due to limited space and the requirement to ensure that the lens allows the sensor to absorb the maximum amount of light, there must be no dirty adhesive on the smartphone camera lens. Therefore, a black adhesive will significantly improve effectiveness. In addition, these components are very sensitive to heat and therefore require an adhesive that can cure at low temperatures.

Properties

Low-temperature curing

High curing speed and high performance

Maximum cost reduction through optimized adhesive distribution

Very low volatile vapor, no effect on optical components

The adhesive is black, contributing to better light acquisition.

Good adhesion to a wide range of materials such as PC, ZEONEX, COC, CO

Recommend Products

Related Solutions

-

NXP Introduces High-Power Wireless Charg...

NXP Semiconductors announced the first high-power wireless charging solution for notebooks and 2-in-...

Apr 28, 2023 Consumer Electronics -

Multifunctional Street Light Automatic C...

The street light automatic controller is suitable for the automatic control of street lights in resi...

Apr 26, 2023 Consumer Electronics -

How Can IoT Solution Providers Build a S...

The Internet of Things (IoT) has been attracting a lot of attention in the industry for its security...

Apr 25, 2023 Consumer Electronics -

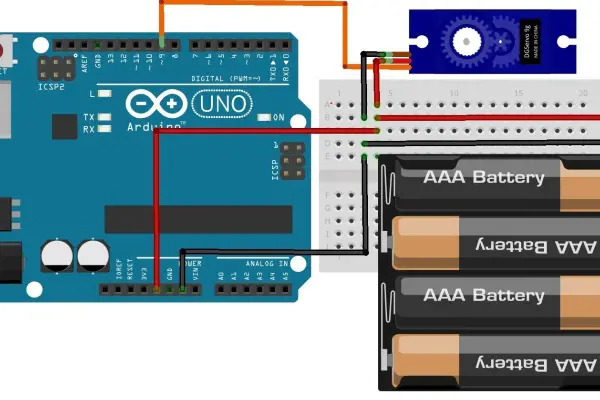

ADI Proposes a Solution for Servo Motor ...

For motor control solutions, ADI offers a comprehensive portfolio of products, including analog-to-d...

Apr 25, 2023 Consumer Electronics -

IoT Transforms and Adds Value to Consume...

The Internet of Things (IoT) is taking consumer electronics to another level and could lead to the n...

Apr 26, 2023 Consumer Electronics -

Texas Instruments Programmable Logic and...

Programmable logic controllers (PLCs) and programmable automation controllers (PACs) process and con...

Apr 26, 2023 Consumer Electronics

Update Time: Apr 28, 2023 Consumer Electronics

Update Time: Apr 28, 2023 Consumer Electronics