ADI Proposes a Solution for Servo Motor Control

Published: Apr 25, 2023

Automation & Control

Share:

Published: Apr 25, 2023

Automation & Control

Share:

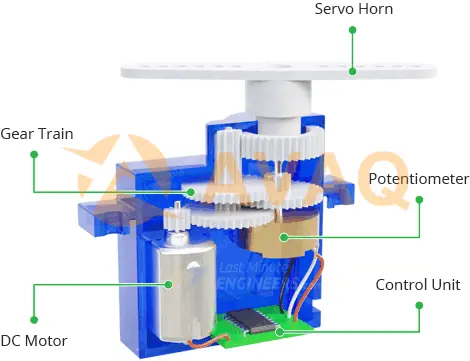

For motor control solutions, ADI offers a comprehensive portfolio of products, including analog-to-digital/digital-to-analog converters, amplifiers, embedded processors, iCoupler® digital isolators, power management devices, and real-time Ethernet solutions. These high-performance devices and increased system integration enable newer topology designs, bringing customer value for system differentiation, such as faster main frequency processors to run more complex algorithms, high-performance ADCs to support higher performance current loop control, and more. The performance of a servo drive system is closely related to the performance and accuracy of the final motion control system that the user builds, which in most cases can be a high-precision CNC machine tool system, a networked motion control system or a robotics system that requires precise control of position and motor torque; ADI offers a complete solution that covers all the important components in the signal chain. ADI offers complete solutions covering all important components in the signal chain.

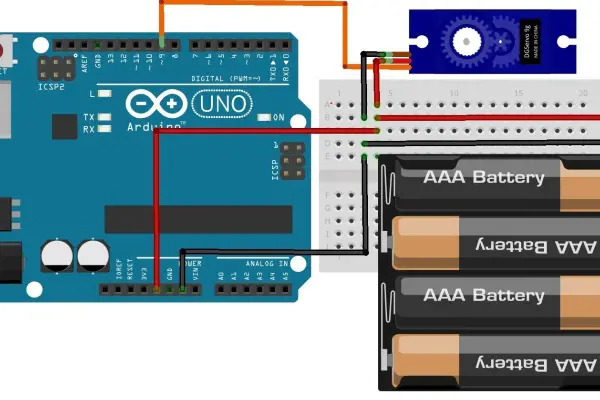

servo-motor-control

System Design Considerations and Key Challenges

>>In servo control, high-accuracy current and voltage sensing improves speed and torque control performance. ADI offers a complete line of ADCs with at least 12-bit accuracy, multi-channel, and simultaneous sampling capabilities.

>> ADI offers the industry's best performance solution based on sigma-delta modulators for servo systems that use resistors for current sampling, where the quality of the sampled signal is critical to current control performance.

>> Position detection performance is key to servo control, often using optical encoders and resolvers as position sensors. The shift from analog to digital servo control technology has driven the development of modern servo systems and met the high demands for performance and efficiency in motor control.

>> ADI offers communication transceivers with iCoupler digital isolators, as well as complete solutions for different communication protocols such as EnDat, Biss, Nikon, Tamagawa, etc.

>> ADI's iCoupler digital isolator products meet the high voltage safety isolation requirements.

>> The performance of the IGBT power device drive protection circuitry determines the reliability and safety of the product, and ADI's power device drive chips have a wealth of integrated protection features to make the design easier and more reliable.

>>High-performance vector control and sensorless control can be achieved using high-performance processors such as DSP.

>> Network solutions that support a wide range of motion control and industrial real-time Ethernet protocols.

>>The use of integrated power factor correction (PFC) controllers makes it easier to achieve the effect of reducing current distortion at the power input of servo systems.

>>Long life cycles and high-reliability IC products are the first choices for engineers designing industrial applications.

>>The shift from common AC induction motors to permanent magnet synchronous motors has been a major trend, requiring system designers to provide higher efficiency and more flexible algorithms.

>>High-performance, real-time industrial control networks enable better synchronization of multiple motors.

Value Proposition of ADI Solutions

For motor control systems, industrial system design requires low power consumption and high efficiency, and ADI offers individual devices and a complete product signal chain to accelerate system design. The company's products include feedback and detection, isolation, power management, interface, embedded processing, and communication. It's safe to say that ADI's broad technology portfolio of world-class isolators, processors, converters, and mixed-signal front ends can meet the needs of engineers for any motor control solution, now and in the future.

Recommend Products

Related Solutions

-

NXP Introduces High-Power Wireless Charg...

NXP Semiconductors announced the first high-power wireless charging solution for notebooks and 2-in-...

Apr 28, 2023 Consumer Electronics -

Multifunctional Street Light Automatic C...

The street light automatic controller is suitable for the automatic control of street lights in resi...

Apr 26, 2023 Consumer Electronics -

How Can IoT Solution Providers Build a S...

The Internet of Things (IoT) has been attracting a lot of attention in the industry for its security...

Apr 25, 2023 Consumer Electronics -

ADI Proposes a Solution for Servo Motor ...

For motor control solutions, ADI offers a comprehensive portfolio of products, including analog-to-d...

Apr 25, 2023 Consumer Electronics -

IoT Transforms and Adds Value to Consume...

The Internet of Things (IoT) is taking consumer electronics to another level and could lead to the n...

Apr 26, 2023 Consumer Electronics -

Texas Instruments Programmable Logic and...

Programmable logic controllers (PLCs) and programmable automation controllers (PACs) process and con...

Apr 26, 2023 Consumer Electronics

Update Time: Apr 25, 2023 Consumer Electronics

Update Time: Apr 25, 2023 Consumer Electronics