How the Car Meets the Electronic Needs

Published: Apr 27, 2023

Automotive Electronics

Share:

Published: Apr 27, 2023

Automotive Electronics

Share:

As automobiles move toward electronics, both conventional fuel vehicles and hybrid/electric vehicles are using more and more electronic components, making the automotive application market booming and bringing huge business opportunities to the electronics industry. In this article, we will introduce you the development of the automotive application market and the solutions introduced by Nexperia.

The rapid development of the automotive electronics market brings huge business opportunities

In addition to the development of automotive applications toward electrification, even fuel vehicles are gradually adding more and more security, lighting, entertainment equipment, using more and more electronic systems, common automotive electronic applications include ADAS radar sensor module, airbag controller, anti-lock braking system, automatic HVAC BLDC motor, cooling fan, electronic fuel injection, electric power steering, adaptive LED headlights, on-board chargers (On-Board Charger, OBC), in-vehicle networks (CAN/LIN/FlexRay), multimedia/infotainment systems, touch screens, cameras, LED lighting, DC/DC converters, etc.

In addition, today's world requires cars to be more energy efficient, and governments around the world are mandating the reduction of CO2 emissions from cars to combat climate change and protect resources.

Thus, the core lies in the powertrain - whether combustion or hybrid or fully electric - and innovative technologies and systems in powertrain, chassis, safety, lighting and body electronics can also help improve the overall efficiency of the vehicle to reduce fuel consumption, CO2 emissions and costs. Today's automobiles are undergoing significant changes, and both vehicle manufacturers and auto parts manufacturers must improve the efficiency and effectiveness of their products in order to respond to changing market needs.

With a wide range of products including bipolar transistors, diodes, electrostatic discharge protection (ESD), transient voltage suppression diodes (TVS), metal oxide semiconductor field-effect transistors (MOSFETs) and logic devices, Nexperia consistently provides products with excellent functionality and performance for automotive applications in Nexperia offers a wide variety of products for the automotive industry, including

Nexperia offers a wide range of specialized discrete, MOSFET and logic devices for the automotive industry that are fully AEC-Q100/Q101 compliant, supporting new system designs with traditional powertrain, chassis and body electronics, Nexperia's innovative solutions are compatible with future designs ranging from wireless automotive safety systems to electric vehicle chargers. Nexperia's innovative solutions support a wide range of new system designs that are compatible with future designs, from wireless automotive safety systems to electric vehicle chargers, and are based on a dedicated manufacturing and supply chain to produce energy-efficient and cleanly designed products that can be delivered in volume over long periods of time. Below you will find highlights of some of Nexperia's key products for your reference.

ESD protection devices that meet the automotive Ethernet specification

To take the next step in automotive connectivity and electrification, high-speed and high-bandwidth automotive Ethernet is needed, and many industry leaders are collaborating within the OPEN Alliance SIG to encourage automotive Ethernet adoption, with the key goal of enabling the deployment of existing IEEE 100BASE-T1/1000BASE-T1 physical layer specifications and complementing compliance and interoperability with specifications, but as more advanced electrical designs become available, discrete ESD protection becomes increasingly important.

Nexperia offers a portfolio of automotive Ethernet ESD protection devices that are AEC-Q101 compliant and IEEE OPEN Alliance 100BASE-T1 and 1000BASE-T1 compliant ESD protection devices designed to protect both bus lines from damage caused by ESD and other transients.

Take Nexperia's PESD2ETH1GXT-Q, PESD1ETH1GLS-Q and PESD1ETH1GXLS-Q, for example. These three devices are silicon-based and offer several advantages over alternative ESD protection solutions such as varistors, providing higher reliability and improved 1 pF (maximum) diode capacitance to ensure better of signal integrity.

Gallium nitride FETs offer high power conversion efficiency

The electrification of automobiles has led to increasing high power requirements and the need to improve power conversion efficiency, reducing power loss is a major challenge for the industry, and gallium nitride (GaN) is expected to become the mainstream technology. Compared with silicon (Si) and silicon carbide (SiC) solutions, GaN technology has shown better performance advantages. Better-performing GaN power transistors are available for higher power and can meet the vehicle specification requirements of electric vehicles.

Nexperia has introduced GaN FET devices in next-generation high-voltage GaN HEMT H2 technology and TO-247 and Nexperia's proprietary CCPAK surface mount packages. The devices achieve superior switching quality factor (FOM) and on-state performance, and improve stability and simplify application design, thanks to their cascaded configuration that eliminates the need for complex drivers and controls.

The new GaN technology uses epitaxial vias to reduce defects and reduce chip size by approximately 24%. In the initial version of the conventional TO-247, the RDS(on) with high threshold voltage and low diode forward voltage is also reduced to just 41 mΩ (maximum, 35 mΩ typical, at 25°C). For the CCPAK surface mount version, this reduction is further increased to 39 mΩ (maximum value, 33 mΩ typical, at 25°C). Because these parts are configured as cascaded devices, they are also easy to drive using standard Si MOSFET drivers, and both versions meet the requirements of AEC-Q101 for automotive applications.

Nexperia continues to invest in the development and expansion of its product portfolio using next-generation GaN processes, initially releasing traditional TO-247 versions and die formats for power module manufacturers, and then introducing high-performance surface mount CCPAK packages. The CCPAK GaN FETs can be used in top or bottom cooling configurations, making them versatile and helping to further improve heat dissipation.

Nexperia's GaN FET devices, including the 650 V GAN041-650WSB in a TO-247 package and the GAN039-650NBB in a CCPAK package, are efficient, cost-effective solutions for high power conversion at 650 V and approximately 30-40 mΩ RDS(on) for applications such as on-board chargers, DC/DC converters in electric vehicles, and traction inverters. DC/DC converters and traction inverters in electric vehicles.

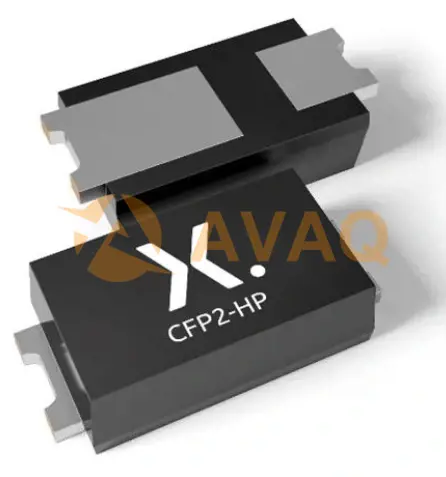

Schottky rectifier diodes with new packaging technology

A Schottky diode is a diode with a low on-state voltage drop that allows for high-speed switching. It is an electronic device that takes advantage of the Schottky energy barrier feature, which generates a voltage drop of about 0.7-1.7 V when current flows through a normal diode, but the voltage drop of a Schottky diode is only 0.15-0.45 V, thus improving the efficiency of the system and producing a rectification effect.

To enhance the performance of Schottky rectifiers, Nexperia introduces trench Schottky rectifiers in a Copper Clip Bond FlatPower (CFP) package that meets the challenging requirements of efficient and space-saving designs.

In modern automotive architectures, the number of electronic control units (ECUs) is decreasing, leaving only high-performance, feature-rich ECUs responsible for front-axle, rear-axle and body control. as a result, the density of diode devices for such units has increased significantly, and to achieve these higher density designs, manufacturers are increasingly relying on modern multilayer PCBs. compared to diode devices using SMA packages, the use of The vertical thermal design of these multilayer PCBs allows designers to save up to 75% of board space. This rugged package design extends the runtime of diode devices and increases board-level reliability, while the new lead shape improves automated optical inspection (AOI) performance.

Nexperia has introduced a variety of rectifier diodes for power applications in a new CFP2-HP package available in standard and AECQ-101 versions, including 45 V, 60 V and 100 V trench Schottky rectifier diodes (with 1 A and 2 A options), such as the PMEG100T20ELXD-Q, a 100 V, 2 A trench Schottky rectifier diode. For applications requiring ultra-fast recovery, Nexperia has also added the 200 V, 1 A PNE20010EXD-Q rectifier diode to its portfolio.

Conclusion

Nexperia has a diverse and complete line of ESD protection devices, power conversion devices, and rectifiers for automotive electronics that can meet the diverse development needs of our customers and are worthy of further investigation and adoption. It is worth your further understanding and adoption.

Recommend Products

Related Solutions

-

NXP Introduces High-Power Wireless Charg...

NXP Semiconductors announced the first high-power wireless charging solution for notebooks and 2-in-...

Apr 28, 2023 Consumer Electronics -

Multifunctional Street Light Automatic C...

The street light automatic controller is suitable for the automatic control of street lights in resi...

Apr 26, 2023 Consumer Electronics -

How Can IoT Solution Providers Build a S...

The Internet of Things (IoT) has been attracting a lot of attention in the industry for its security...

Apr 25, 2023 Consumer Electronics -

ADI Proposes a Solution for Servo Motor ...

For motor control solutions, ADI offers a comprehensive portfolio of products, including analog-to-d...

Apr 25, 2023 Consumer Electronics -

IoT Transforms and Adds Value to Consume...

The Internet of Things (IoT) is taking consumer electronics to another level and could lead to the n...

Apr 26, 2023 Consumer Electronics -

Texas Instruments Programmable Logic and...

Programmable logic controllers (PLCs) and programmable automation controllers (PACs) process and con...

Apr 26, 2023 Consumer Electronics

Update Time: Apr 27, 2023 Consumer Electronics

Update Time: Apr 27, 2023 Consumer Electronics