Siemens is Committed to Automation and Digital Solutions, Leading Industrial Production a Step Further

Published: Apr 27, 2023

Automation & Control

Share:

Published: Apr 27, 2023

Automation & Control

Share:

Based on SPS Connect, the online platform of SPS in Nuremberg, Germany, Siemens will hold the "SPS Discussion: Digital Enterprise" event online to comprehensively showcase its new products, services and solutions in its digital enterprise business portfolio , enabling discrete manufacturing and process industry companies to respond to rapidly changing market demands and environments. Siemens is committed to integrating cutting-edge technologies such as artificial intelligence, edge and cloud computing, or additive manufacturing into automation and digital solutions to enhance the intelligence and flexibility of production, thereby leading industrial production a step further.

New products on display include the ready-to-use open platform Industrial Edge, new edge devices, and edge applications for driving. In addition, Siemens will launch a new generation of distributed drive systems. The innovations showcased this year also include Siemens TIA Portal-based multi-vendor robot programming solutions, Cloud Connect innovative products for integrated data access, and new interconnection and remote collaboration services.

The adoption of cloud and edge technologies enables the digitization of manufacturing processes, making operations more flexible and efficient. The Siemens Industrial Edge open platform can be used to create industrial IoT solutions at the machine level. This platform can help customers bring more applications to the shop floor in a shorter time, further improving the productivity of machines and factories, while reducing implementation and operating costs.

Siemens will soon launch the Industrial Edge Management System, a centralized and scalable company-wide infrastructure for managing networked edge devices and applications. Combined with existing software and hardware products, the Industrial Edge V1.0 open platform provides users with a ready-to-use seamless solution. Siemens has also added hardware offerings to its Industrial Edge portfolio.

The processor technology adopted by Simatic IPC227E industrial PC can support Nanobox and panel PC at the same time. Thanks to its outstanding performance and numerous interfaces, the Simatic IPC227E industrial PC is the ideal carrier for Industrial Edge and artificial intelligence (AI) applications.

In the field of drive technology, Siemens has extended the MindSphere application Analyze MyDrives with an edge version. This will be the edge application launched for drive technology on the market, perfectly interpreting the intelligent interconnection of edge and cloud computing. In the field of predictive services for drive systems, Siemens has intelligently upgraded MindSphere-based service applications.

In the release, the Predictive Service Assistance application has integrated AI algorithms to support customers who need to enhance the availability of monitored assets and improve repair efficiency. Sinamics G115D is a new generation of Siemens distributed drive system, specially developed for horizontal conveyor systems. As a complete drive system, it consists of three parts: motor, frequency converter and gearbox.

Continuous changes in product variants and external markets require more flexible machines, while the application of handling and assembly systems also means a higher degree of automation. This is supported by the integration of robotics in production machines. With the Simatic Robot Library for Simatic Robot Integrator (Simatic Robot Integrator), Siemens offers a new universal robot library for the TIA Portal.

In the future, users will be able to program most of the robots in the TIA Portal using the Simatic Robot Library, independent of the manufacturer, and can also adopt standard operating concepts based on the Simatic Robot Integrator and Simatic HMI. With the TIA Portal's standard environment, users can save up to 30 percent of their time when designing new complete systems, thereby reducing time to market.

Siemens showcased its innovative Cloud Connect cloud connectivity products, which serve as the basis for current and future industrial IoT applications and provide continuous data access through all interfaces and standards. The web-based process control system Simatic PCS neo, on the basis of secure network connection, supports convenient system access and provides customers with a multi-user collaborative work platform. Siemens also highlighted the benefits of its Power over Ethernet (PoE) portfolio, a key component of the digitalization of modern enterprises.

All new PoE switches comply with the IEEE 802.3bt standard in view of the growing market demand for components that can be quickly installed and operated at the desired location without complex wiring. With the Module Type Package (MTP), Siemens offers the right solution for plant operators who want to quickly and flexibly expand or change production.

In the field of digital enterprise services, Siemens provides a series of new services. Digital Factory Optimization (Digital Factory Optimization) uses artificial intelligence technology to simulate and optimize the production and logistics environment. Virtual Commissioning Services (Virtual Commissioning Services) Siemens experts architect, implement and maintain digital twins of production lines, equipment and plants for web-based virtual commissioning.

In addition, new interconnection services (Connectivity Services) can be connected between production networks from any data source and higher-level information systems (such as edge devices, data acquisition and monitoring systems (SCADA), manufacturing execution systems (MES), enterprise Establish connections between resource planning systems (ERP) or cloud systems. The new Remote Collaboration Services (Remote Collaboration Services) enable remote fast and comprehensive engineering design as well as fault diagnosis and correction.

Recommend Products

Related Solutions

-

NXP Introduces High-Power Wireless Charg...

NXP Semiconductors announced the first high-power wireless charging solution for notebooks and 2-in-...

Apr 28, 2023 Consumer Electronics -

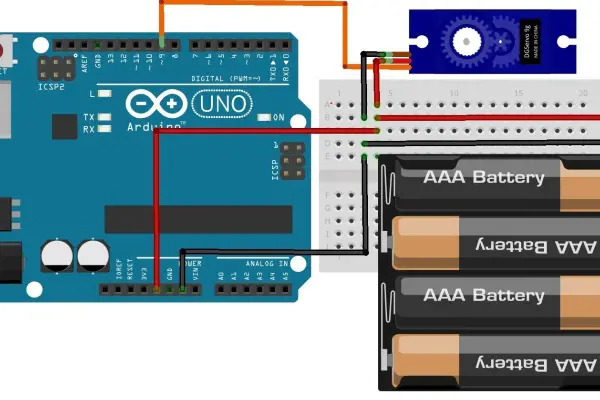

Multifunctional Street Light Automatic C...

The street light automatic controller is suitable for the automatic control of street lights in resi...

Apr 26, 2023 Consumer Electronics -

How Can IoT Solution Providers Build a S...

The Internet of Things (IoT) has been attracting a lot of attention in the industry for its security...

Apr 25, 2023 Consumer Electronics -

ADI Proposes a Solution for Servo Motor ...

For motor control solutions, ADI offers a comprehensive portfolio of products, including analog-to-d...

Apr 25, 2023 Consumer Electronics -

IoT Transforms and Adds Value to Consume...

The Internet of Things (IoT) is taking consumer electronics to another level and could lead to the n...

Apr 26, 2023 Consumer Electronics -

Texas Instruments Programmable Logic and...

Programmable logic controllers (PLCs) and programmable automation controllers (PACs) process and con...

Apr 26, 2023 Consumer Electronics

Update Time: Apr 27, 2023 Consumer Electronics

Update Time: Apr 27, 2023 Consumer Electronics