Industrial Robot Motor Control Solution

Published: Apr 27, 2023

Automation & Control

Share:

Published: Apr 27, 2023

Automation & Control

Share:

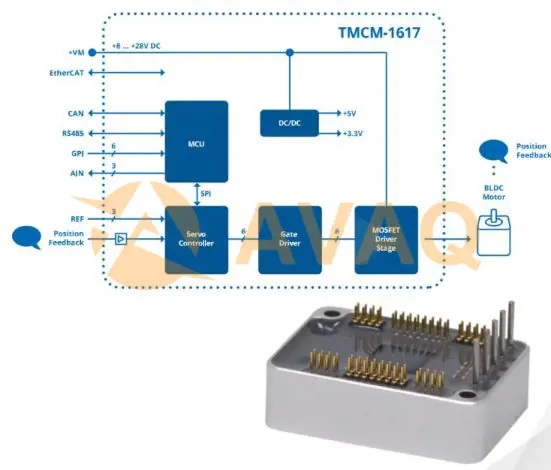

Trinamic, now part of Maxim Integrated, showcased a range of power control solutions at the forefront of APEC, including its latest solution to simplify end-of-arm tooling (EoAT) development for industrial robots and a single-axis servo controller/ driver. In an interview with Power Electronics, Jeff DeAngelis, vice president of industrial communications at Maxim Integrated, along with Jonas Proeger, director of business management, and Stephan Kubisch, director of product definition at Trinamic, highlight these latest solutions that can speed development of various industrial automation applications.

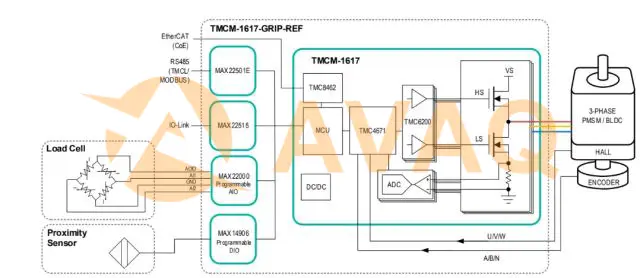

The TMCM-1617-GRIP-REF open source reference design integrates a hardware field-oriented controller (FOC) and three communication ports. It includes Maxim Integrated's MAX22000 industrial-grade IC, the MAX22515 IO-Link transceiver, a software-configurable high-precision analog I/O, and the MAX14906, a quad digital I/O configured for single-channel operation. Axis servo drive.

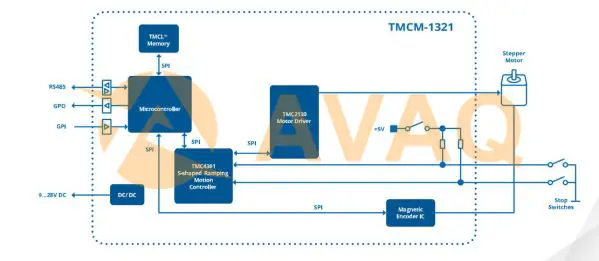

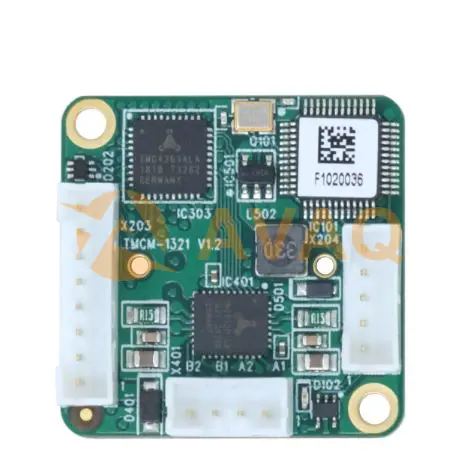

The new TMCM-1321 servo controller/driver module is designed to optimize the performance of two-phase bipolar stepper motors by optimizing shaft speed and synchronization and reducing power loss. According to Maxim Integrated, the device integrates a magnetic encoder and a digital input for an optical encoder to simplify servo control with advanced feedback and diagnostics.

Open Source Platform

"The advantage of the TMCM-1617-GRIP-REF reference design is its ability to integrate on a single board multiple circuits that are typically distributed across multiple boards or components at the end of a robotic arm. This compact footprint combines Simplified communication bus interface that reduces wiring harness burden and provides a simplified way of transferring data and power over single or double pair wires, as well as the ability to properly debug tools.This compact size and simplified communication and configuration bus interface Combined with our TMCL-IDE software development environment, this makes it a very versatile reference design for end-of-arm tools," said DeAngelis. "Besides the compact size, another important factor is the very low weight of the module at 24 grams," he added.

As Proeger described, the block diagram in Figure 1 shows a load cell that detects force from an arm or gripper or a proximity sensor. TMCM-1617-GRIP-REF supports industrial communication protocols EtherCAT, IO-Link and RS-485, and provides analog signals and software programmable digital input/output, and can use Trinamic Motion Control Language Integrated Development Environment (TMCL-IDE). “We have an option for RS-485 communication at 100 megabits per second, which is still very popular. The advantage is that it is still a traditional high-speed cabling, which can meet the needs of this application. From a communication perspective, this is a very flexible product and a more traditional approach to motor control," Proeger said.

"We provide all the necessary power rails to support external peripherals and sensors without the need for additional power supplies," Kubisch said. "Perfect current control has the greatest impact on overall system efficiency," he added.

With a state-of-the-art bus architecture combined with integrated control and diagnostics in a single solution, Maxim Integrated believes the reference design can improve productivity on the factory floor and bring artificial intelligence to the edge. For example, the MAX22515 onboard features include extensive integrated protection to ensure robust communications in harsh industrial environments. All IO-Link line interface pins (V24, C/Q, DI, and GND) are reverse-voltage protected, short-circuit protected, hot-swap protected, and have integrated ±1.2kV/500Ω surge protection.

For the future of motor and motion control, increasing complexity associated with eventual reliability requirements will lead to smarter systems – and this needs to be at the edge, decentralized. Decisions need to be made in real time and data needs to be collected at the source and shared in the cloud.

Servo Controller/Driver TMCM-1321

The TMCM-1321 is a single-axis controller/driver for two-phase bipolar stepper motors with integrated magnetic encoder and digital inputs, all of which provide closed-loop control logic for optimized motor control.

Maxim Integrated notes that its form factor is designed to be significantly smaller than other solutions, and that the board supports 256x microstepping and noise-free operation. When a suitable magnet is attached to the motor shaft, an integrated magnetic encoder can be used, allowing closed-loop operation. Alternatively, an optical encoder can be connected via the ABN digital input. Different ramp shapes can be selected. In addition to the linear and Trinamic SixPoint™ ramps, the TMCM-1321 module implements an S-shaped ramp that speeds up the actual transfer time.

The TMCM-1321 is designed for coil currents up to 0.7A RMS and 24V DC supply voltage. Three digital inputs can be used as end switch and home switch inputs or as general purpose inputs.

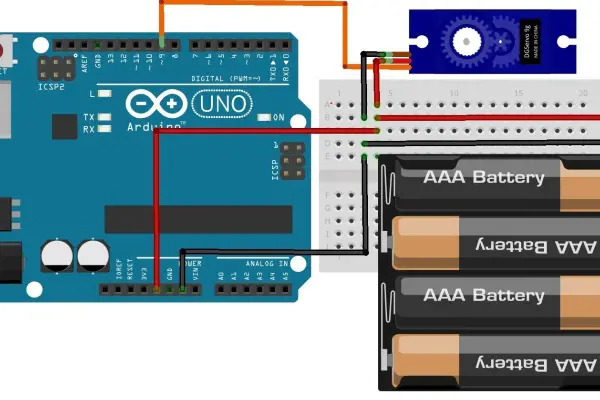

Motor controls and drives are fundamental to many applications as they can achieve a high degree of precision which translates into lower cost and higher efficiency. An important function performed by the motor control circuit is to ensure that the rotor acquires an accurate position with respect to the windings under different operating and load conditions so that its position can be determined with sufficient accuracy.

Recommend Products

Related Solutions

-

NXP Introduces High-Power Wireless Charg...

NXP Semiconductors announced the first high-power wireless charging solution for notebooks and 2-in-...

Apr 28, 2023 Consumer Electronics -

Multifunctional Street Light Automatic C...

The street light automatic controller is suitable for the automatic control of street lights in resi...

Apr 26, 2023 Consumer Electronics -

How Can IoT Solution Providers Build a S...

The Internet of Things (IoT) has been attracting a lot of attention in the industry for its security...

Apr 25, 2023 Consumer Electronics -

ADI Proposes a Solution for Servo Motor ...

For motor control solutions, ADI offers a comprehensive portfolio of products, including analog-to-d...

Apr 25, 2023 Consumer Electronics -

IoT Transforms and Adds Value to Consume...

The Internet of Things (IoT) is taking consumer electronics to another level and could lead to the n...

Apr 26, 2023 Consumer Electronics -

Texas Instruments Programmable Logic and...

Programmable logic controllers (PLCs) and programmable automation controllers (PACs) process and con...

Apr 26, 2023 Consumer Electronics

Update Time: Apr 27, 2023 Consumer Electronics

Update Time: Apr 27, 2023 Consumer Electronics