What is the Classification of Mechanical Comparators?

Published: Apr 28, 2023

Published: Apr 28, 2023

Contents

What is Mechanical Comparator?

Comprised of mechanical methods like gears, bars, pinions & racks, a mechanical comparator is a measuring tool to get the magnification. These kinds of ways are primarily used for multiplying the means' activity to boost the precision of the tool.

Main Features

- Dial Indicator

- Determining Variety

- Sensitivity

- High Accuracy

- Get in touch with Factors

- Boosting Mechanism

- Easy to Use

- Mobile

- Resilient

Working Concept

The working concept of mechanical comparators is based upon the principle of mechanical boosting, which allows for specific as well as precise measurement of small differences in the dimensions of a work surface and a reference criterion.

To make use of a mechanical comparator, the workpiece is brought into contact with the referral criterion and the call factor is adapted to zero the dial sign. The workpiece is then relocated far from the recommendation criterion and also the dial indicator will reveal the difference in their dimensions.

Types of Mechanical Comparators

Dial Indicators

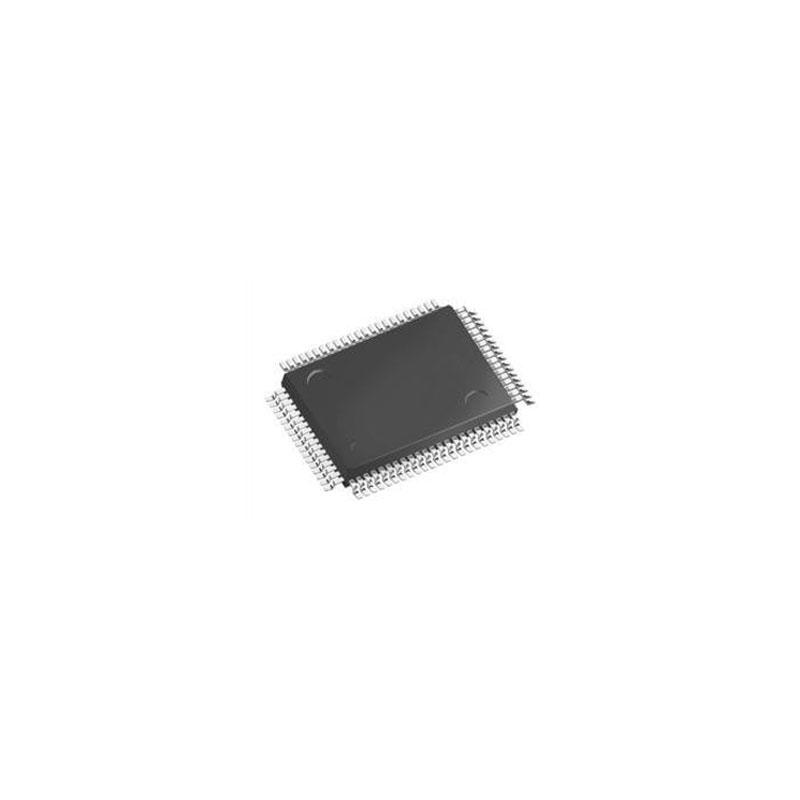

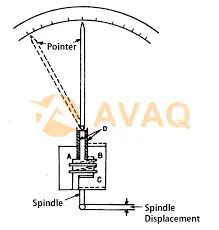

A dial sign, also known as a clock sign, a dial gauge, a probe indicator, or a comparator, is a gauging instrument that can be used in numerous sectors where precision is essential, such as production, creating, and scientific companies. The sign is a spring-loaded pin, or bettor, attached to a clock-faced dial. As the spindle moves in and out of the sign, a needle on the dial reveals the measurement of the range, which in turn discloses the depth of the clinical depression. Utilizing this tool is typically rather straightforward. A driver lifts the indicator's spindle with a lever, moves the product she or he wishes to gauge under it, and reduces the spindle. If the component varies from the reference, the sign's dial signs up the variance. On some indications with a larger variety, a smaller sized face within the larger tracks each transformation.

The dial indicator includes a needle or pointer that moves along a dial or range, suggesting the inconsistency of the workpiece dimension from the referral criterion. The amplification system ensures that also tiny differences in the measurements of the workpiece as well as the reference requirement are identified as well as displayed on the dial indicator.

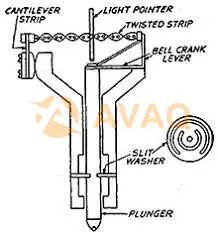

Read type Comparators

The read type mechanical comparator consists of a pin, obstructs, reeds, needle and a graduated range. At first, with the help of slip evaluates or scale blocks, the whole comparator is adjusted to absolutely no range. After that the work to be determined or analysed is kept under the plunger call point.

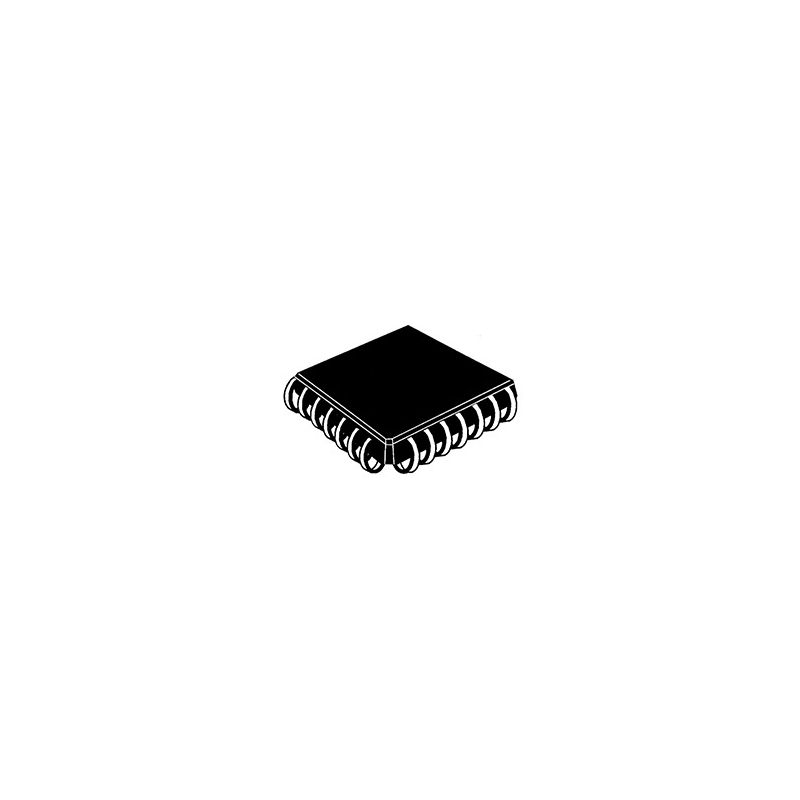

Johanson Mikro kator

A Johansson Mikrokator (likewise called Abramson's activity) used to get mechanical magnifying of the difference in length as compared to a requirement is a mechanical comparator. It works on the concept of a button rotating on a loophole of string. A twisted thin steel strip holds a guideline, which shows the reading on an appropriate range. Because there is no rubbing associated with the transfer of movement from the strip to the pointer, it is free from reaction. It was apparently developed by Hugo Abramson in 1938.

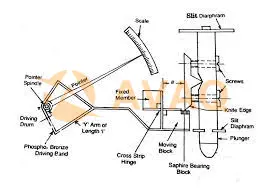

Sigma Comparators

Sigma comparator is a mechanical comparator presented by an U.S.A. instruments producing firm. They are generally used to measure the roughness of the surface area by computing the dimensional difference in between the measured value and also the conventional worth of the surface product.

Applications

- The mainly usage of a reed-type mechanical comparator is to determine the dimensional discrepancy of the work surface by the typical dimensions.

- This comparator is utilized in mass production & research laboratory testing for evaluation purposes.

- This comparator is mostly used in different production firms like an external rings, bearing internal, bearing cages race, as well as vehicle cylindrical parts.

- A mechanical optical comparator is used to increase the bettor's movement through a mechanical & optical elements.

- These comparators serve in gauging the surface roughness by measuring the dimensional variant in between the standard & determined worth of the surface area product.

FAQ

FAQ

- What is a comparator?

- The function of a comparator is to compare two or more data items to determine whether they are equal or not, or to determine the relationship between them in terms of size and order of arrangement, which is called a comparison. The circuit or device that can perform this comparison function is called a comparator. A comparator is a circuit that compares an analog voltage signal with a reference voltage. The two inputs of a comparator are analog signals and the output is a binary signal 0 or 1. The output remains constant as the difference between the input voltages increases or decreases and the positive and negative signs remain constant.

Popular Industry Focus

Popular Industry Focus

Hot Products

-

![TDA21535]()

TDA21535

Infineon Technologies AG

OEMs, CMs ONLY (NO BROKERS)

-

![VLDR1235G]()

VLDR1235G

Vishay Semiconductor Opto Division

Standard LEDs - SMD Red 624nm 14,500mcd 2.2V Gull Wing

-

![HCPL-0601-500E]()

HCPL-0601-500E

Broadcom Limited

High Speed Optocouplers with 10MBd and 5mA

-

![SM8S36AHE3/2D]()

SM8S36AHE3/2D

Vishay General Semiconductor - Diodes Division

58.1V Clamp 114A Ipp Tvs Diode Surface Mount DO-218AB

-

![AD536AKH]()

AD536AKH

Analog Devices Inc.

Power Management Specialized - PMIC RMS/DC CONVERTER IC

-

![LPC2220FBD144]()

LPC2220FBD144

NXP Semiconductors

16/32-bit ARM microcontrollers; flashless, with 10-bit ADC and external memory interface

Related Parts

-

![Hi3519V101]()

Hi3519V101

HISILICON

-

![H5AN4G8NAFR]()

H5AN4G8NAFR

SKHYNIX

-

![KLM8G2FEJA]()

KLM8G2FEJA

SAMSUNG

eMMC – 64GB

-

![RTL8304E]()

RTL8304E

REALTEK

-

![RTL8101]()

RTL8101

REALTEK

REALTEK SINGLE CHIP FAST ETHERNET CONTROLLER WITH POWER MANAGEMENT

-

![AR8033-AL1A-R]()

AR8033-AL1A-R

ATHEROS

PHY 3-CH 10Mbps/100Mbps/1Gbps 1.1V/2.62V/3.3V 48-Pin QFN EP T/R

-

![QM52015]()

QM52015

QORVO

-

![BCM3553XKFEB5G]()

BCM3553XKFEB5G

BROADCOM

-

![AMD-762]()

AMD-762

AMD

AMD-762 - AMD-762 System Controller Data Sheet

-

![QMI519]()

QMI519

Allegro MicroSystems

-

![4T-30]()

4T-30

APITech

RF Connectors / Coaxial Connectors

Update Time: May 15, 2023 Consumer Electronics

Update Time: May 15, 2023 Consumer Electronics