Thin and Thick Film IC: What are the Differences 2023

Published: Jul 07, 2023

Published: Jul 07, 2023

Contents

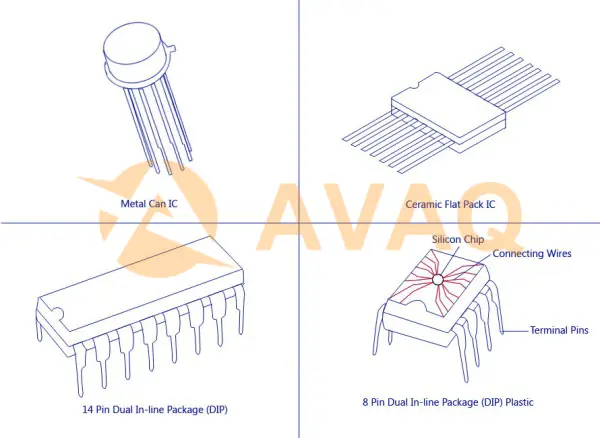

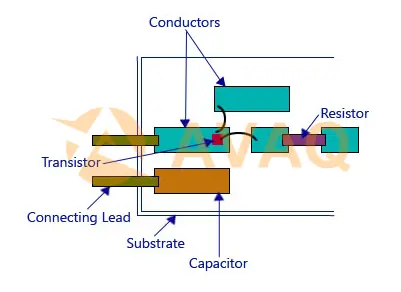

Thin film and thick film integrated circuits (ICs) are two popular fabrication techniques used in the production of electronic circuits. These techniques involve depositing layers of conductive and insulating materials onto a substrate to create the necessary circuitry. Thin film ICs utilize thin layers of materials, typically metal, while thick film ICs employ thicker layers of materials, often a combination of metals and ceramics.

In this article, we will explore the differences between thin film and thick film ICs, examining their fabrication processes, characteristics, and applications. Whether you are an electronics enthusiast, a student, or a professional engineer, understanding the distinctions between thin film and thick film ICs will empower you to make informed decisions when selecting the appropriate fabrication technique for your circuit designs.

Part1. What is Thin and Thick Film IC

1. Thin-film ics

Thin-film ICs, also known as thin-film integrated circuits, are a type of electronic circuits that are fabricated using thin-film deposition techniques. These ICs are made by depositing thin layers of various materials, such as metals or semiconductors, onto a substrate, typically a glass or ceramic material.

1) Features of Thin-film ics

- Miniaturization: Thin-film ICs are known for their compact size and high component density.

- High Frequency Operation: They can operate at high frequencies, making them suitable for applications requiring fast signal processing.

- Customizability: Thin-film ICs can be tailored to specific requirements by adjusting the deposition parameters and layer compositions.

- High Reliability: These ICs are built using stable and durable materials, contributing to their overall reliability and longevity.

- Wide Range of Applications: Thin-film ICs find applications in various fields, including aerospace, telecommunications, consumer electronics, medical devices, and automotive electronics.

2) Application of the thin-film ics

|

IC Model |

Manufacturer |

Application |

|

AD8221 |

Analog Devices (ADI) |

Precision Instrumentation Amplifiers |

|

Maxim Integrated |

Low-Noise, Precision Op Amp |

|

|

LTC2484 |

Linear Technology (LTC) |

24-Bit ADC with Integrated PGA |

|

AD8302 |

Analog Devices (ADI) |

RF/IF Gain and Phase Detector |

|

MAX1486 |

Maxim Integrated |

RS-485/RS-422 Transceiver |

|

AD8561 |

Analog Devices (ADI) |

Single-Supply, Rail-to-Rail Op Amp |

|

AD9748 |

Analog Devices (ADI) |

Digital-to-Analog Converter (DAC) |

|

LTC1043 |

Linear Technology (LTC) |

Micropower Voltage Comparator |

|

ONC15AA |

ON Semiconductor |

Digital Temperature Sensor |

|

IHLP6767GZER2R2M1R3 |

Vishay Intertechnology |

Thin Film High Power Inductor |

2. Thick-film ics

Thick-film ICs, also known as thick-film integrated circuits, are a type of electronic circuits that are fabricated using a thick-film deposition process. Unlike thin-film ICs that use thin layers of materials, thick-film ICs are built by printing thick layers of conductive, resistive, and dielectric materials onto a substrate.

1) Features of thick-film ics

- Versatility: Thick-film ICs offer flexibility in material selection and layer composition, allowing for various circuit elements and interconnections.

- Integration of Passive Components: They can integrate passive components directly onto the substrate during the printing process, enabling compact and integrated circuit designs.

- Cost-effectiveness: Thick-film ICs are generally more cost-effective due to batch production and the ability to use a variety of substrate materials.

- Wide Applications: They find applications in automotive electronics, industrial control systems, consumer electronics, and medical devices for sensors, power management, and signal conditioning circuits.

- Thermal Stability: Thick-film ICs exhibit good thermal stability, allowing them to operate reliably under different temperature conditions.

- Design Flexibility: The printing process allows for easy prototyping and design modifications, making it suitable for rapid development cycles and custom applications.

2) Application of the thick-film ics

|

IC Model |

Manufacturer |

Application |

|

DS2430 |

Maxim Integrated |

Memory storage for smart cards |

|

LM317T |

Texas Instruments (TI) |

Adjustable voltage regulators |

|

Microchip Technology |

Capacitive touch sensing |

|

|

Analog Devices (ADI) |

Precision instrumentation amplifier |

|

|

MCP4725 |

Microchip Technology |

Digital-to-Analog Converter (DAC) |

|

LM35 |

Texas Instruments (TI) |

Temperature sensor |

|

MAX31865 |

Maxim Integrated |

Resistance temperature detector (RTD) interface |

|

M62429 |

Renesas Electronics |

Digital volume control |

|

CS5460 |

Cirrus Logic |

Energy metering and power monitoring |

|

Texas Instruments (TI) |

Current sensor and power monitor |

Part 2. What are the Differences between Thick and Thin Film IC

Thick-film ICs and thin-film ICs are two distinct types of integrated circuits that differ in their fabrication processes, materials used, and overall characteristics.

In short,

|

Characteristic |

Thick-Film ICs |

Thin-Film ICs |

|

Fabrication Process |

Screen printing or stencil printing |

Deposition techniques (sputtering, evaporation) |

|

Layer Thickness |

Relatively thick (micrometers to tens of micrometers) |

Relatively thin (nanometers to micrometers) |

|

Miniaturization |

Moderate level |

High level |

|

Frequency Response |

Lower frequency range |

Higher frequency range |

|

Customizability |

Limited options |

Greater flexibility |

|

Cost |

Relatively cost-effective |

Potentially higher cost |

|

Applications |

Automotive electronics, industrial control systems, medical devices |

Telecommunications, aerospace, high-frequency signal processing |

Fabrication Process: Thick-film ICs are typically created by screen printing or stencil printing thick layers of conductive, resistive, and dielectric materials onto a substrate. In contrast, thin-film ICs are fabricated by depositing thin layers of materials onto a substrate through techniques such as sputtering or evaporation.

Layer Thickness: Thick-film ICs have relatively thicker layers of materials, typically in the range of a few micrometers to tens of micrometers. Thin-film ICs, on the other hand, have significantly thinner layers, usually in the range of a few nanometers to a few micrometers.

Miniaturization: Thin-film ICs allow for higher levels of miniaturization due to their thinner layers and ability to achieve a higher component density on a given substrate area. Thick-film ICs, while still capable of miniaturization, have limitations in achieving the same level of compactness as thin-film ICs.

Frequency Response: Thin-film ICs are better suited for high-frequency applications due to their thinner layers, which result in lower parasitic capacitance and inductance. Thick-film ICs typically have lower frequency response capabilities compared to thin-film ICs.

Customizability: Thin-film ICs offer more flexibility and customizability in terms of material selection, layer composition, and deposition techniques. This allows for precise control over the properties and characteristics of the thin films. Thick-film ICs offer some degree of customizability, but their options may be more limited compared to thin-film ICs.

Cost: Thick-film ICs generally offer a more cost-effective solution compared to thin-film ICs. The screen printing or stencil printing process used in thick-film IC fabrication is less expensive and allows for batch production. Thin-film ICs, with their more complex deposition techniques, may involve higher production costs.

Applications: Thick-film ICs are commonly used in automotive electronics, industrial control systems, and medical devices. They are suitable for applications that require integration of passive components and moderate performance requirements. Thin-film ICs find applications in areas such as telecommunications, aerospace, and high-frequency signal processing, where high precision, miniaturization, and high-frequency operation are crucial.

Part 3. Thick and Thin film IC: Which is Better

Determining whether thick-film or thin-film ICs are better depends on the specific requirements of your application. Both technologies have their own advantages and limitations. Here are some factors to consider:

Advantages of Thick-Film ICs:

- Cost-effective manufacturing process

- Integration of passive components

- Suitable for moderate-performance applications

- Good thermal stability

Advantages of Thin-Film ICs:

- High miniaturization capability

- High frequency response

- Customizability in terms of material selection and properties

- Suitable for high-performance applications

To determine which technology is better for your application, consider the following:

🔔Performance Requirements: Assess the specific performance specifications needed for your application, such as frequency range, precision, noise levels, and power handling. Determine if thick-film or thin-film ICs can meet those requirements.

🔔Space Constraints: Evaluate the space available for your circuit design. If miniaturization is crucial, thin-film ICs may be a better choice due to their higher component density and smaller form factor.

🔔Cost Considerations: Consider your budget and cost constraints. Thick-film ICs are generally more cost-effective due to simpler manufacturing processes, while thin-film ICs may involve higher production costs.

🔔Customization Needs: Determine if your application requires precise control over material selection, layer composition, or other properties. Thin-film ICs offer more flexibility in customization compared to thick-film ICs.

🔔Manufacturing Capabilities: Assess the manufacturing capabilities and expertise available to produce either thick-film or thin-film ICs. Consider factors such as equipment availability, process complexity, and required expertise.

Conclusion

In conclusion, thin film and thick film ICs are two widely used fabrication techniques in the production of electronic circuits. Thin film ICs offer precise control, high performance, and compatibility with integrated circuit technologies. On the other hand, thick film ICs provide cost-effectiveness, flexibility, and the ability to integrate passive components.

Understanding the differences between thin film and thick film ICs will enable you to select the most suitable fabrication technique for your specific application requirements. Stay updated with the latest advancements in IC fabrication, explore datasheets and technical documentation, and make informed choices when designing electronic circuits. Embrace the advantages offered by both thin film and thick film ICs and unlock new possibilities in electronic circuit design and functionality.

FAQ

FAQ

- Can thin-film and thick-film ICs be customized for specific applications?

- Yes, thin-film and thick-film ICs can be customized to meet specific application requirements. Manufacturers can tailor the deposition processes, layer thicknesses, and materials used to achieve desired electrical properties, performance characteristics, and compatibility with the target application.

- What are the typical materials used in thin-film and thick-film ICs?

- In thin-film ICs, materials such as tantalum nitride (TaN), titanium nitride (TiN), silicon dioxide (SiO2), and various metals like gold (Au) and platinum (Pt) are commonly used. In thick-film ICs, materials such as conductive pastes containing silver (Ag), resistive pastes containing ruthenium oxide (RuO2), and dielectric pastes containing glass and ceramic materials are often employed.

- What are some typical applications of thin-film and thick-film ICs?

- Thin-film ICs are commonly used in applications such as precision instrumentation, sensors, medical devices, and high-frequency communication systems. Thick-film ICs find applications in power electronics, automotive electronics, industrial controls, and consumer electronics.

Popular Industry Focus

Popular Industry Focus

Hot Products

-

![2N1724A]()

2N1724A

Microchip

Bipolar (BJT) Transistor NPN 120 V 5 A 3 W Stud Mount TO-61

-

![PIC16F1517-I/PT]()

PIC16F1517-I/PT

MICROCHIP

RISC architecture for efficient operation

-

![ATXMEGA128D3-AU]()

ATXMEGA128D3-AU

Microchip

With a high level of integration and advanced features, the ATXMEGA128D3-AU is a popular choice for embedded system designers

-

![SST25VF040B-50-4I-SAE]()

SST25VF040B-50-4I-SAE

MICROCHIP

4Mb 2.7-3.6V SPI Serial Flash.

-

![24LC128T-I/MNY]()

24LC128T-I/MNY

MICROCHIP

128Kb I2C compatible 2-wire Serial EEPROM.

-

![24LC02BT-I/OT]()

24LC02BT-I/OT

Microchip

256 x 8 I2C/2-wire serial EEPROM

Related Parts

-

![LPC2220FBD144]()

LPC2220FBD144

NXP Semiconductors

16/32-bit ARM microcontrollers; flashless, with 10-bit ADC and external memory interface

-

![NH82801HBM-SLB9A]()

NH82801HBM-SLB9A

INTEL

CONTROLLER HUB, ICH8M, I/O, 82801HBM

-

![DM9161CEP]()

DM9161CEP

DAVICOM SEMICONDUCTOR INC

Network Interface

-

![AMBE-2000]()

AMBE-2000

Digital Voice Systems Inc

PCM Codec, A/MU-Law, 1-Func, PQFP100, TQFP-100

-

![SC1200UCL-266]()

SC1200UCL-266

NATIONAL SEMICONDUCTOR CORP

Multifunction Peripheral, CMOS, PBGA432

-

![RPIXP2400BAT]()

RPIXP2400BAT

Intel

Intel® IXP2400 Microprocessor IC Intel® IXP2400 1 Core, 32-Bit 600MHz 1356-FCBGA (37.5x37.5)

-

![ALC268-GR]()

ALC268-GR

REALTEK SEMICONDUCTOR CORP

Consumer Circuit, PQFP48

-

![88E1111-B2-CAA1C000]()

88E1111-B2-CAA1C000

MARVELL SEMICONDUCTOR INC

Ethernet Transceiver, 1-Trnsvr, CMOS, ROHS COMPLIANT, BCC-96

-

![IP113ALF]()

IP113ALF

Ic Plus Corp

Network Interface

-

![HL7692_1103454]()

HL7692_1103454

Sierra Wireless

Cellular EDGE, GPRS, GSM, LTE Transceiver Module 900MHz, 1.8GHz Antenna Not Included Surface Mount

-

![FW82801CA SL632]()

FW82801CA SL632

Intel Corp

I/O Controller 421-Pin BGA

-

![uPD71059GB-3B4]()

uPD71059GB-3B4

Renesas Technology Corp

Interrupt Controller 44-Pin PQFP

-

![DLP-RFID1]()

DLP-RFID1

DLP Design Inc.

Interface Development Tools DLP Module

-

![BGM121N256V2]()

BGM121N256V2

Silicon Labs

Bluetooth Bluetooth v4.2 Transceiver Module 2.4GHz Antenna Not Included, Castellation Surface Mount

-

![BGM210P022JIA2]()

BGM210P022JIA2

Silicon Labs

BGM210P Blue Gecko module, +10 dBm, 2.4 GHz, 1024 kB Flash, -40 to 125 C, Chip antenna or RF pin

Update Time: Jul 10, 2023 Consumer Electronics

Update Time: Jul 10, 2023 Consumer Electronics