3 Aspects to Learn about Artificial Intelligence in Electronics 2023

Published: Oct 25, 2023

Published: Oct 25, 2023

Contents

Part 1. Artificial Intelligence in Electronics Industry

Artificial Intelligence (AI) has a significant impact on the electronics industry across various aspects, including research and development (R&D), manufacturing, and security.

R&D:

Prominent electronics equipment manufacturers such as Samsung, Mitsubishi, and Hitachi are actively investing in long-term AI research programs to explore commercial applications and enhancements for their product range. Their research efforts are focused on machine vision, voice recognition, audio processing, and other key AI-related areas. These initiatives aim to gain a deeper understanding of usage contexts, user behavior, preferences, and needs.

- Product Design and Innovation: AI can assist in product design by analyzing massive datasets to identify emerging trends, customer preferences, and market demands. This helps in creating more competitive and innovative products.

- Simulation and Prototyping: AI-powered simulations can model and test electronic components and systems more efficiently. This reduces the need for physical prototypes and speeds up the development process.

- Materials Research: AI algorithms can help discover and optimize new materials for electronics, enhancing their performance and durability.

- Quality Control: AI systems can be used to detect and predict potential issues in the design and manufacturing of electronic components, ensuring higher quality products.

Manufacturing:

In addition to the development of AI-powered electronics devices with transformative benefits for various industries, the electronics manufacturing sector is leveraging AI to revolutionize product development cycles, enhance product design processes, reduce defects, and accelerate product launches. AI-enabled manufacturing fosters agile workflows by harnessing anonymized data from diverse sources, including product-attached sensors, customer usage patterns, current market dynamics, audio and video files, technician feedback, and product manuals. This data-driven approach empowers electronic companies to optimize product quality, cut costs, and respond to market demands more efficiently.

- Process Optimization: AI is used to optimize manufacturing processes, such as semiconductor fabrication and PCB assembly, by monitoring equipment performance and adjusting parameters in real-time for better efficiency.

- Predictive Maintenance: AI-driven predictive maintenance can reduce downtime by monitoring machinery for signs of wear and tear, scheduling maintenance before critical failures occur.

- Quality Assurance: Computer vision and machine learning algorithms can inspect products for defects, ensuring higher quality and reducing production costs.

- Supply Chain Management: AI helps in managing the supply chain more efficiently by predicting demand, optimizing inventory, and improving logistics.

Security:

With the proliferation of smart and connected devices in the electronics industry, security has become a paramount concern. Manufacturers are incorporating built-in security features in these devices to bolster their protection. AI plays a pivotal role in this domain by analyzing traffic patterns, establishing performance baselines, monitoring user behavior, and swiftly identifying anomalies in real-time. AI-powered security systems are not only enhancing general security but are also safeguarding electronic devices against potential infiltrations, vulnerabilities, and cyberattacks, thereby bolstering overall security in the industry.

- Cybersecurity: In the electronics industry, protecting intellectual property, sensitive data, and manufacturing processes is crucial. AI can be used for threat detection, anomaly detection, and monitoring network traffic to detect and prevent cyberattacks.

- Physical Security: AI-powered surveillance systems can enhance physical security in manufacturing facilities by identifying and responding to security breaches.

- Access Control: AI can be used for biometric access control systems, such as facial recognition or fingerprint scanning, to secure sensitive areas within electronic manufacturing facilities.

- Data Encryption and Privacy: AI can help in implementing advanced encryption algorithms to protect sensitive data during transmission and storage.

How is AI used in electronics? --Applications

Predictive Maintenance: AI is utilized in the electronics manufacturing industry to predict equipment failures and prevent costly downtime. By analyzing sensor data, AI algorithms can detect patterns indicative of potential issues and alert maintenance teams before a breakdown occurs.

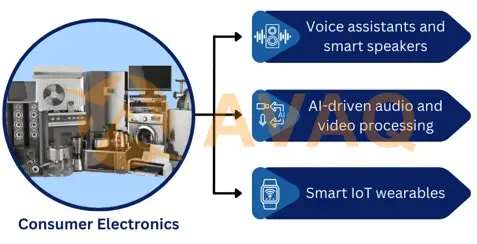

Voice and Speech Recognition: AI-powered voice recognition systems are prevalent in consumer electronics, such as smartphones, smart speakers, and automotive infotainment systems. They enable users to interact with devices using voice commands and natural language.

Autonomous Navigation: Drones and robots often incorporate AI for autonomous navigation. Through a combination of sensors, cameras, and AI algorithms, these devices can perceive their environment, avoid obstacles, and navigate autonomously.

Image and Video Analysis: AI is used in electronics for image and video analysis, particularly in surveillance and security systems. AI algorithms can detect and track objects, recognize faces, and analyze video feeds for security and monitoring purposes.

Natural Language Processing: Consumer electronics like smart speakers and virtual assistants rely on AI-driven natural language processing (NLP) to understand and respond to spoken or written language. NLP enables devices to answer questions, provide information, and perform tasks.

Gesture Recognition: AI is employed in gaming consoles and interactive devices for gesture recognition. Cameras and sensors can track users' movements and gestures, allowing them to control and interact with games and applications in a more immersive manner.

Machine Vision: In electronics manufacturing, AI-powered machine vision systems are used for quality control and inspection. These systems can detect defects, measure dimensions, and ensure that products meet specific quality standards.

Part 2. The Impact of Artificial Intelligence on the Electronic Component Supply Chain

Not only will the semiconductor industry produce AI chips, but the chips themselves can be used to improve the efficiency of the electronic component supply chain.What's included in an AI chip includes GPUs, field-programmable gate arrays (FPGAs), and application-specific integrated circuits (ASICs) dedicated to AI.

CPUs are common components used for basic AI tasks, but they are used less frequently as AI technology evolves. The power of AI depends on the number and size of transistors it uses. The more and smaller the transistors, the more advanced the AI chip.

AI chips need to perform a lot of calculations in parallel rather than sequentially, and the data they process is huge.

AI chips are integrated circuit chips specifically designed to perform artificial intelligence (AI) tasks. These chips employ highly optimized hardware and software architectures designed to accelerate the execution of machine learning and deep learning algorithms, thereby improving the performance and efficiency of AI applications.AI chips play a key role in a number of fields, including self-driving cars, smartphones, IoT devices, cloud computing data centers, and more.

AI chips typically have the following characteristics:

- Parallel computing power: AI chips are able to process large amounts of data at the same time through parallel computing units, thus accelerating the training and inference of deep learning models.

- Dedicated hardware: These chips use hardware specifically designed for AI tasks, such as tensor processing units (TPUs), graphics processing units (GPUs), and neural network processing units (NPUs).

- Low power consumption: AI chips are typically designed to consume low power to accommodate mobile devices and embedded systems.

- Efficient data transfer: These chips usually have high-speed data transfer interfaces for fast communication with storage and networking devices.

- Deep learning support: AI chips have built-in optimization libraries and frameworks for deep learning tasks to provide support for a wide range of neural network models.

It has been proposed that AI chips and networks be designed to operate in reference to the human brain. What if the chips acted similarly to neuronal synapses, sending information only when needed rather than working continuously. For this use, non-volatile memory on a chip would be a good option for AI. This type of memory can hold data without a power source and therefore does not require a constant supply. If it is combined with processing logic, a system-on-chip processor can be realized.

Although designs were created for the AI chips, production was an extraordinary challenge. The size and cost of the nodes required to produce these chips is often too high to be profitable. As structures become smaller, such as moving from the 65nm node to the latest 5nm, costs soar. 65nm costs $28 million to develop, while 5nm costs $540 million to develop. Similarly, fab construction for the same two nodes increases in price from $400 million to $5.4 billion.

Major companies have been investing in the development of AI chip infrastructure. However, at each stage of the development and manufacturing process, significant capital investment is required.

Since AI infrastructure, is set up exclusively for its intended use, manufacturers also need to be highly specialized. This means that the entire supply chain of manufacturers who have not yet specialized can cost millions of dollars to transform.

Artificial Intelligence The use of AI in the electronic component distribution industry can revolutionize the way people work and can maximize profits for a company. It can help companies with supply forecasting, optimizing inventory, scheduling deliveries, and more.

At every step of the electronics supply chain, AI and machine learning can accomplish time-consuming tasks. At the sales stage, AI can assist with customer segmentation and dynamic pricing, which is a rarity in the current market. It can also prevent possible errors in the manufacturing process and improve the intelligence of manufactured ICs and semiconductors.

Part 3. Future of Artificial Intelligence in Electronics

The future of artificial intelligence (AI) in the electronics industry is promising, but it does come with certain challenges and concerns that may be causing hesitation.

Future Developments:

Advanced AI Algorithms: As AI research continues to advance, we can expect more robust and accurate algorithms. Machine learning and deep learning models will become more reliable, improving AI's performance in electronics applications.

AI Integration: AI integration into electronics will likely become more streamlined and less complex. Tools and platforms for AI implementation will become more user-friendly, reducing the complexity of adoption.

Cost-Efficiency: Over time, the cost of AI hardware is expected to decrease as technology matures. This will make AI more accessible to a broader range of companies in the electronics industry.

Energy Efficiency: Efforts are being made to develop AI hardware that is more energy-efficient. Future AI chips may consume less power while delivering high-performance computing.

Hesitations and Concerns:

Implementation Complexity: Integrating AI into existing electronics systems can be complex. Companies may hesitate due to the challenges of transitioning to AI-driven processes and the need for specialized expertise.

Algorithm Robustness and Accuracy: Concerns about the reliability of AI algorithms persist. Addressing issues related to false positives, false negatives, and algorithm bias is crucial to ensure that AI delivers accurate results.

Extra Hardware Cost: The initial investment in AI hardware and infrastructure can be a deterrent. Companies need to weigh the potential benefits against the upfront costs.

Energy Consumption: AI computations can be computationally intensive, leading to high energy consumption. Green AI initiatives are focusing on developing more energy-efficient AI solutions to address this concern.

FAQ

FAQ

- How is AI contributing to the development of autonomous vehicles?

- AI plays a crucial role in autonomous vehicles by enabling real-time object detection, path planning, and decision-making. AI algorithms process data from sensors like lidar, radar, and cameras to make driving decisions, enhancing safety and convenience.

- Are there AI chips or hardware specifically designed for AI applications in electronics?

- Yes, there are AI-specific hardware accelerators and chips designed for AI tasks. These include graphics processing units (GPUs), field-programmable gate arrays (FPGAs), and application-specific integrated circuits (ASICs) tailored for AI workloads. They offer high performance and energy efficiency for AI tasks.

- What is machine learning in the context of AI in electronics?

- Machine learning is a subset of AI that involves training algorithms to learn from data and make predictions or decisions without being explicitly programmed. In electronics, machine learning is used for tasks such as anomaly detection, classification, and optimization.

hmc994apm5e

Popular Industry Focus

Popular Industry Focus

Hot Products

-

SY88022ALMG

Microchip Technology, Inc

Laser Driver IC 11.3125Gbps 1 Channel 3V ~ 3.6V 16-QFN (3x3)

-

PIC16C55-HS/SO

Microchip Technology, Inc

8-bit Microcontrollers - MCU .75KB 24 RAM 20 I/O HSC SOIC-28

-

23A256-I/SN

Microchip Technology, Inc

1.5-1.95V 256Kb SPI Serial SRAM.

-

AGL250V2-CSG196I

Microchip Technology, Inc

Ultra Low Density FPGAs.

-

MCP3913A1-E/MV

Microchip Technology, Inc

24-Bit, 125kSPS, 6-Ch Simultaneous Sample ADC.

-

ZL50060GAC

Microchip Technology, Inc

Digital Bus Switch ICs

Related Parts

-

FW82801AA

Intel Corp

PCI Hub Controller USB 1.1 PCI, SMBus Interface 241-BGA (23x23)

-

UPD6708GS-E1-A

Renesas Technology Corp

IEBUS (INTER EQUIPMENT BUS) PROTOCOL CONTROL LSI

-

J-N3-B3E6-LY

Telit

GNSS Receiver Module

-

W83877ATF

Nuvoton Technology Corporation

I/O Controller Phase Controller 100-Pin PQFP

-

TMPZ84C10AP-6

Toshiba Semiconductor

Direct Memory Direct Controller

-

BA843

ROHM Semiconductor

Tape Deck Key Controller 16-Pin PDIP

-

NEO-M8N-0-10

U-Blox

NEO-M8 RF Receiver BeiDou, Galileo, GLONASS, GNSS, GPS 1.575GHz -167dBm

-

FW82801AA SL3Z2

Intel Corp

CHIPSET FOR APPLIED COMPUTING

-

82801DBM

Intel Corp

I/O Controller 421-Pin BGA

-

ADE7763ARSRL

Analog Devices, Inc

Single Phase Meter IC 20-SSOP

-

ANX9804

Analogix Semiconductor

Multimedia Converter DVO/LVTTL to Display Port/HDMI 2560x1600Pixels 2.7Gbps 81-Pin BGA Tray

-

MN5572

Panasonic Corporation

Gray Scale Font Engine 100-Pin LQFP

-

DMF2011-224

Skyworks Solutions, Inc

Diode RF Mixer Schottky 2V 75mW 4-Pin

-

AD9889KSTZ-80

Analog Devices, Inc

Video Transmitter IC I²C HDCP 1.1, HDMI 1.1 80-LQFP (14x14) Package

-

AT97SC3205-U3A1200B

Microchip Technology, Inc

Microchip Technology

Update Time: Oct 27, 2023 Consumer Electronics

Update Time: Oct 27, 2023 Consumer Electronics