The Ultimate Guide to Power Management Integrated Circuits 2023

Published: Oct 16, 2023

Published: Oct 16, 2023

Contents

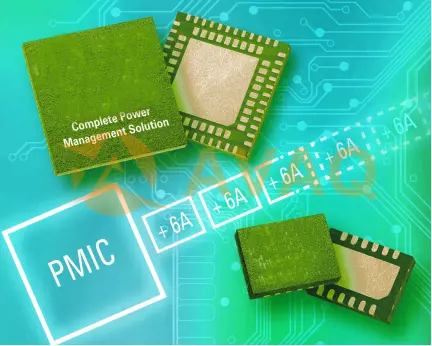

Part 1. What is Power Management Integrated Circuit(PMIC)

A Power Management Integrated Circuit (PMIC) is a semiconductor component designed to manage and optimize power supply within electronic devices. It performs various critical functions, including regulating voltage levels for different components, controlling power startup and shutdown sequences, managing battery charging and discharging, monitoring power consumption, and providing protection against voltage and current irregularities. PMICs are essential for improving energy efficiency, extending battery life, and ensuring the reliable and safe operation of electronic devices by efficiently handling power-related tasks.

Main Parameters of Power Management IC Chips

- Power Consumption: The power consumption of a power management IC chip is an important parameter that reflects the energy consumption of the chip. Power management IC chip power consumption is usually divided into static power consumption and dynamic power consumption. Static power consumption refers to the power consumption in the standby state of the chip, while dynamic power consumption refers to the power consumption in the running state of the chip.

- Conversion efficiency: conversion efficiency is another important parameter of the power management IC chip, which reflects the efficiency of the chip to convert the input power into output power. Power management IC chip conversion efficiency is usually divided into input efficiency, output efficiency and application efficiency.

- Voltage regulation accuracy: voltage regulation accuracy refers to the power management IC chip on the input voltage regulation accuracy. The higher the voltage regulation accuracy, the more stable the output voltage of the chip.

- Current control accuracy: current control accuracy refers to the power management IC chip on the output current control accuracy. The higher the current control precision, the more stable the output current of the chip.

- Temperature control accuracy: temperature control accuracy refers to the power management IC chip on the chip temperature control accuracy. The higher the temperature control accuracy, the more stable the chip's temperature.

- Response speed: response speed refers to the power management IC chip response to the speed of the input signal. The faster the response speed, the more accurate the control of the chip.

- Reliability: Reliability refers to the performance of the power management IC chip in long-time use and frequent switching. The higher the reliability, the longer the life of the chip.

Part 2. Types of Power Management Integrated Circuit(PMIC)

1. Classification of power management IC chips

I. Classification by function

1) System power management IC chip

System power management IC chip is a kind of chip used to manage the power supply of the whole electronic equipment, which can realize voltage regulation, current control, energy saving and other functions. System power management IC chip is usually used in close cooperation with the CPU, the power supply of electronic equipment can be fine management, so as to improve the performance and stability of the equipment.

2) Battery management IC chip

Battery management IC chip is a chip used to manage the battery power supply, which can realize the battery charging, discharging control, as well as battery power monitoring and other functions. Battery management IC chip can manage the battery finely according to the battery voltage, current and other information to improve the life and performance of the battery.

3) Power management IC chip

The power management IC chip is a chip used to manage the power of electronic devices, which can realize the reasonable distribution and management of power to improve the performance and efficiency of the device. Power management IC chip can regulate and optimize the power supply of the equipment, so as to achieve the purpose of energy saving and prolonging battery life.

2. Classification of voltage regulation

1) Linear regulation IC chip

Linear regulation IC chip is a kind of chip used to regulate the voltage, it can be linearly regulated by the way, the input voltage into the required output voltage. Linear regulation IC chips have the advantage of high conversion efficiency and low power consumption, but the disadvantage is that the output voltage accuracy is not high.

2) Proportional-integral-derivative IC chips

The proportional-integral-derivative IC chip is a chip that regulates the input voltage by means of proportional, integral, or differential regulation to stabilize the output voltage. The advantages of proportional-integral-derivative IC chip are high output voltage precision and high conversion efficiency, but its disadvantage is large power consumption.

3. Current control mode classification

1) Open-circuit regulation IC chip

Open-circuit regulation IC chip is a kind of chip used for controlling current, which can regulate the input current through the open-circuit way, so as to realize the stabilization of output current. The advantage of the open-circuit regulation IC chip is that the output current can be precisely controlled, but its disadvantage is that the circuit is complex and the power consumption is large.

2) Closed-loop regulation IC chip

Closed-loop regulation IC chip is a kind of chip used to control the current, which can regulate the input current in a closed-loop way to stabilize the output current. The advantages of closed-loop regulation IC chip are high output current precision and low power consumption, but its disadvantages are complex circuit and slow control speed.

In actual use, according to the specific requirements of the equipment, should choose the appropriate power management IC chip, in order to achieve the best power management effect.ICGOO website will continue to update the article, to provide users with the latest technical information and product information, to help users to understand and select the most suitable components for their needs.

2. 8 Common Types of PMIC

The dominant part of the power management semiconductor book is the power management IC, and the dominant part of the power management semiconductor book is the power management IC, which can be broadly categorized into the following eight types.

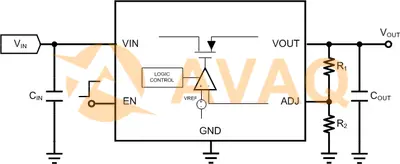

1. LDO - the most basic power supply IC, is a low dropout linear regulator, the use of transistors or field effect tubes (FETs) operating in its saturation region, from the application of the input voltage is subtracted from the excess voltage to produce a regulated output voltage. The dropout voltage is defined as the minimum value of the difference between the input voltage and the output voltage required for the regulator to maintain the output voltage within 100mV above or below its rated value. Positive output LDO (low dropout) regulators typically use a power transistor (also known as a pass-through device) as the PNP. this transistor allows saturation, so the regulator can have a very low dropout voltage, typically around 200mV, compared to the dropout of around 2V for a conventional linear regulator with an NPN composite supply transistor. A negative output LDO uses an NPN as its transfer device and operates in a similar mode to the PNP device of a positive output LDO;

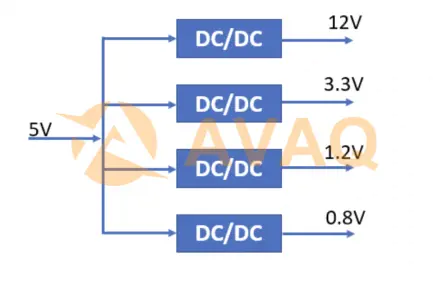

2. DC / DC - refers to the direct current circuit will be a voltage value of the electrical energy into another voltage value of the electrical energy of the device, is a newly developed miniaturized power switching module, it is the use of microelectronics technology, small surface-mounted integrated circuits and micro-electronic components assembled into a single unit to form a. DC -DC power supply module is conducive to simplifying the power supply circuit design to shorten the development cycle, to achieve the best indicators, etc., can be widely used in various types of digital instruments and intelligent instruments;

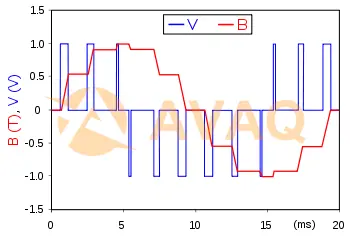

3. PWM - Pulse Width Modulation, is an analog control method, according to the corresponding load change to modulate the transistor base or MOS tube gate bias, to realize the transistor or MOS tube conduction time change, so as to realize the switching regulator power supply output change. This method enables the output voltage of the power supply to remain constant when the operating conditions change, and is a very effective technique for controlling analog circuits using digital signals from microprocessors. Pulse width modulation is a very effective technique to control analog circuits using the digital output of a microprocessor, which is widely used in many fields from measurement and communication to power control and conversion.

4. Power MOSFET - that is, the gate of the metal layer (M) across the oxide layer (O) using the effect of the electric field to control the semiconductor (S) field effect transistor. Power MOS field effect transistor is also divided into junction type and insulated gate type, but usually mainly refers to the insulated gate type in the MOS type (Metal Oxide Semiconductor FET), referred to as power MOSFET (Power MOSFET). The junction type power field effect transistor is generally called electrostatic induction transistor (Static Induction Transistor - SIT). It is characterized by the gate voltage to control the drain current, drive circuit is simple, requires little drive power, fast switching speed, high operating frequency, thermal stability is better than the GTR, but its current capacity is small, low voltage, generally only applies to the power does not exceed 10kW power electronic devices;

5. AC / DC modulation IC - contains a low-voltage control circuit and high-voltage switching transistors;

6. Battery charging and management IC - including battery charging, protection and power display IC, as well as battery data communication "smart" battery IC;

7. Hot plug board control IC - (eliminating the impact of inserting or removing another interface from the working system);

8. MOSFET or IGBT switching function ic.

Among these power management ICs, voltage regulation ICs are a part of the fast developing and yielding ones. Various power management ICs are basically linked to some related applications, so more types of devices can be listed for different applications.

Part 3. Features of Power Management Integrated Circuit(PMIC)

A Power Management Integrated Circuit (PMIC) encompasses various features, including battery management, voltage regulation, and charging capabilities. It often incorporates a DC to DC converter for dynamic voltage scaling, and certain models achieve remarkable power conversion efficiency levels of up to 95%. Additionally, some PMICs integrate dynamic frequency scaling in a combined approach referred to as DVFS (dynamic voltage and frequency scaling).

Manufactured using the BiCMOS process, PMICs are available in different package types, with the QFN (Quad Flat No-Lead) package being common. They can also feature communication interfaces such as I²C or SPI for input and output operations.

Many PMIC models include a low-dropout regulator (LDO) and a real-time clock (RTC) that works alongside a backup battery for timekeeping.

PMICs employ various modulation techniques, including pulse-frequency modulation (PFM) and pulse-width modulation (PWM). Some also utilize switching amplifiers, like Class-D electronic amplifiers, to efficiently manage power in electronic devices.

Part 4. Applications of Power Management Integrated Circuit(PMIC)

Here are common applications of PMICs,

- Mobile Devices: PMICs are crucial in smartphones, tablets, and wearable devices. They regulate voltage levels, manage battery charging, and ensure power efficiency to extend battery life.

- Laptops and Notebooks: PMICs provide power regulation and battery management for laptops, ensuring efficient power usage and charging.

- IoT Devices: In Internet of Things (IoT) applications, PMICs help manage power for sensors, communication modules, and microcontrollers, optimizing energy consumption for long battery life.

- Data Centers: PMICs are used to manage power distribution and conversion in servers and data center equipment to enhance energy efficiency and reduce operating costs.

- Automotive Electronics: PMICs regulate power for various systems within a vehicle, including infotainment, navigation, engine control, and safety systems. They play a critical role in ensuring reliable and efficient operation.

- Industrial Control Systems: In manufacturing and automation, PMICs manage power for sensors, controllers, and actuators, providing precise and stable power supplies.

- Consumer Electronics: PMICs are used in a wide range of consumer devices, including gaming consoles, smart TVs, and digital cameras, to optimize power usage and prolong battery life.

- Wearable Technology: PMICs are essential for wearables like smartwatches and fitness trackers, managing power to support various sensors and communication modules.

- Medical Devices: PMICs regulate power for medical equipment, such as patient monitors, portable diagnostic devices, and implanted devices, ensuring reliability and patient safety.

- Telecommunications Equipment: PMICs are used in networking equipment like routers, switches, and base stations to manage power efficiently and ensure continuous operation.

- Aerospace and Defense: In aviation and defense applications, PMICs control power for avionics, radar systems, and communication equipment, emphasizing reliability and performance.

- Renewable Energy Systems: PMICs are employed in solar inverters and wind turbine controllers to manage power conversion, distribution, and grid connection.

- Audio and Video Equipment: PMICs are used in audio amplifiers, video displays, and other entertainment devices to regulate power and improve energy efficiency.

- Electric Vehicles (EVs): In electric cars and hybrid vehicles, PMICs are integral to battery management, power conversion, and control of electric drivetrains.

- Gaming Consoles: PMICs are utilized in gaming consoles to manage power distribution and thermal management for CPUs and GPUs.

- RFID and NFC Devices: PMICs play a role in RFID readers and NFC devices by managing power to support communication and data transfer.

- Smart Home and Building Automation: PMICs are used in smart thermostats, lighting control, and security systems to manage power efficiently and support various sensors and communication interfaces.

Part 5. Advantages and Disadvantages of Power Management Integrated Circuit(PMIC)

Here are some of the main advantages and disadvantages of using PMICs:

Advantages:

Efficient Power Management: PMICs enable precise and efficient regulation of power, ensuring that electronic devices receive the right voltage levels for optimal performance. This leads to improved energy efficiency and longer battery life in portable devices.

Integration: PMICs often combine multiple functions in a single chip, such as voltage regulation, sequencing, and protection features. This integration reduces the need for external components and simplifies design.

Space Savings: The compact size of PMICs is beneficial for small form factor devices, as they occupy minimal physical space, leaving more room for other components or enabling smaller, sleeker device designs.

Customization: Many PMICs are programmable or configurable, allowing designers to tailor the power management solution to the specific requirements of their device.

Protection Features: PMICs typically offer protection against overvoltage, undervoltage, and overcurrent, which safeguards the device and its components from potential damage.

Sequencing Control: PMICs manage the orderly power-up and power-down of various components in a device, preventing issues like inrush current and ensuring system reliability.

Battery Management: In devices with rechargeable batteries, PMICs manage battery charging and discharging, extending battery life and ensuring safety.

Monitoring and Diagnostics: PMICs often provide real-time data on power consumption and battery status, facilitating system monitoring and diagnostics.

Disadvantages:

Complexity: While PMICs simplify power management, they can be complex to configure and program, especially for designers who are not familiar with their intricacies.

Cost: High-quality PMICs can be relatively expensive, particularly for advanced or specialized functions. This cost needs to be balanced against the benefits they provide.

Design Constraints: PMICs may not offer the same level of flexibility as discrete power components, making them less suitable for highly specialized or custom applications.

Heat Dissipation: In applications with high power dissipation, the heat generated by PMICs may require additional thermal management solutions.

Vendor Lock-In: Using a specific PMIC may tie a designer to a particular manufacturer's ecosystem, potentially limiting choices for future design iterations.

Availability: Certain niche or specialized PMICs may have limited availability, which can be a concern for designers working on unique projects.

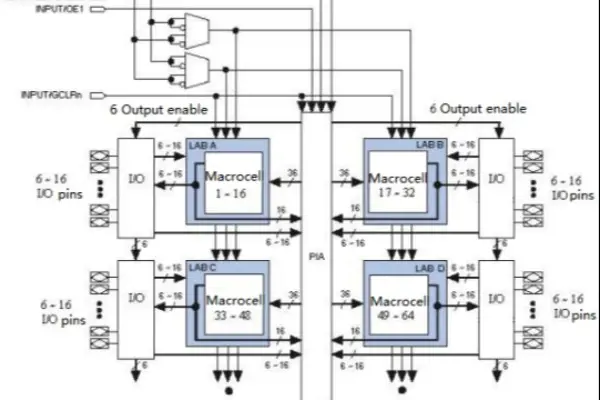

📕 Further Reading: What is Complex Programmable Logic Device(CPLD)

Part 6. Main Manufactures of Power Management Integrated Circuit(PMIC)

|

Manufacturer |

Representative Product |

Features and Characteristics |

Applications |

|

Texas Instruments (TI) |

TPS65982, TPS650861 |

Extensive product range, high efficiency, integrated solutions |

Mobile devices, IoT, automotive |

|

Maxim Integrated |

MAX77650, MAX77751 |

High integration, low power consumption, small form factor |

Wearable devices, portable electronics |

|

Analog Devices (ADI) |

ADP505x, ADP509x |

Precision voltage regulation, advanced power monitoring |

Industrial, automotive, communications |

|

STMicroelectronics |

STPMIC1, ST1PS01 |

Wide voltage input range, digital control interfaces |

Consumer electronics, automotive |

|

ON Semiconductor |

NCP3902, NCP171 |

High-efficiency power conversion, compact designs |

Mobile devices, automotive |

|

Renesas Electronics |

ISL9x61, ISL9x53 |

Advanced power sequencing, voltage monitoring, and protection |

Embedded systems, industrial control |

|

Infineon Technologies |

IPQ40xx, XDPL8218 |

Advanced power management algorithms, versatile solutions |

Data centers, automotive, industrial |

|

NXP Semiconductors |

PF8200, PF3000 |

Scalable power solutions, integrated charger controllers |

Automotive, IoT, portable devices |

|

Dialog Semiconductor |

DA9062, DA9063 |

Highly efficient solutions, low standby power consumption |

Smartphones, tablets, wearable devices |

|

ROHM Semiconductor |

BD71847AMWV, BD71847AMWV-M |

Small form factors, power management for always-on devices |

IoT, wearables, automotive |

FAQ

FAQ

- How do I choose the right PMIC for my device?

- To choose the right PMIC, consider factors like input voltage range, output voltage requirements, power efficiency, available features (e.g., battery management, power sequencing), and your specific application needs. It's advisable to consult with the PMIC manufacturer or distributor for guidance.

- What are some well-known PMIC manufacturers?

- Several semiconductor manufacturers produce PMICs, including Texas Instruments, Maxim Integrated, Analog Devices, STMicroelectronics, NXP Semiconductors, and Renesas, among others.

- Are there specific PMICs for different types of devices?

- Yes, there are PMICs designed for specific device categories. For example, there are PMICs optimized for mobile devices, wearables, automotive systems, and industrial applications. These PMICs are tailored to meet the unique power requirements of those applications.

- What is the difference between a PMIC and a voltage regulator?

- A voltage regulator is one component within a PMIC. PMICs typically contain multiple power-related functions, including voltage regulation, voltage conversion, battery management, and power sequencing. A voltage regulator is specifically responsible for maintaining a stable output voltage.

- Can PMICs be customized for specific applications?

- Yes, PMICs can often be customized or configured to suit the specific requirements of a device or application. Manufacturers may provide options for adjusting voltage levels, power sequencing, and other parameters to tailor the PMIC to a particular use case.

ADP5052ACPZ-R7 In Stock: 5930 $3.512

Popular Industry Focus

Popular Industry Focus

Hot Products

-

LT6301IFE#TR

Analog Devices, Inc

High Speed Operational Amplifiers LT6301 - Dual 500mA, Differential xDSL Line Driver in 28-Lead TSSOP Package

-

AD5934YRSZ

Analog Devices, Inc

<p>250 kSPS, 12-Bit Impedance Converter, Network Analyzer</p>

-

HMC983LP5ETR

Analog Devices, Inc

Fractional-N Divider and Frequency sweeper 32-Pin QFN EP T/R

-

LTC1060ACN

Analog Devices, Inc

Active Filter Dual SW-CAP UNIV 4th Order 20kHz 20-Pin PDIP N

-

AD5280BRUZ50

Analog Devices, Inc

Single/Dual, +15 V/±5 V, 256-Position, I<sup>2</sup>C-Compatible Digital Potentiometer

-

AD5767BCPZ-RL7

Analog Devices, Inc

12 Bit Digital to Analog Converter 16 40-LFCSP-WQ (6x6)

Related Parts

-

BLK-89

Mini-Circuits

DC Block 0.1MHz to 8000MHz SMA(Female)/SMA(Male)

-

X3C07F1-02S

TTM Technologies Inc

Signal Conditioning

-

18A-20

Spectrum Control(API Technologies)

RF Connectors / Coaxial Connectors ATTENUATOR 18A 18GHZ 20DB

-

BDCN-20-13+

Mini-Circuits

Signal Conditioning BI-DIR COUP / SURF MT / RoHS

-

2450BL15B100E

Johanson Technology, Inc

Signal Conditioning 2.45GHz 1:2 IMPEDANCE BALUN

-

DPX165950DT-8030A1

TDK Corporation of America

RF Diplexer Single 2400MHz to 2500MHz/4900MHz to 5950MHz 6-Pin

-

ATS-1M1F-06DB2W

Amphenol Corporation

Fixed Attenuator 6GHz Bag

-

TC1-6+

Mini-Circuits

Audio Transformers / Signal Transformers TC XFMR / SURF MOUNT / RoHS

-

QCN-12+

Mini-Circuits

Signal Conditioning PWR SPLTR CMBD / SM / RoHS

-

B39781B7939P810

Qualcomm (RF360 - A Qualcomm & TDK Joint Venture)

RF Duplexer 746MHz ~ 756MHz / 777MHz ~ 787MHz 9-SMD, No Lead

-

2450DP15K5400E

Johanson Technology, Inc

RF Diplexer 2400MHz to 2500MHz/4900MHz to 5950MHz 6-Pin T/R

-

MAX2620EUA+T

Maxim Integrated

RF IC RF Oscillator Cellular, NPCS, WSM 10MHz ~ 1GHz Buffered Outputs 8-uMAX/uSOP

-

MABA-011085

MACOM Technology Solutions

Signal Conditioning Transformer, 1:1 Balun with tertary wind

-

BD0205F5050AHF

TTM Technologies Inc

RF Balun 70MHz ~ 1GHz 50 / 50Ohm 1608 (4121 Metric)

-

SP-2W1+

Mini-Circuits

Signal Conditioning PWR SPLTR CMBD / SM / RoHS

Update Time: Oct 18, 2023 Consumer Electronics

Update Time: Oct 18, 2023 Consumer Electronics