Difference between PCB and Integrated Circuit (FAQs)

Published: Jun 21, 2023

Published: Jun 21, 2023

Contents

Printed Circuit Boards (PCBs) and Integrated Circuits (ICs) are two fundamental components in the world of electronics. While both PCBs and ICs play crucial roles in electronic systems, they serve different purposes and have distinct characteristics.

Understanding the difference between PCBs and ICs is essential for anyone involved in electronics design and development.

Part 1. What is PCB

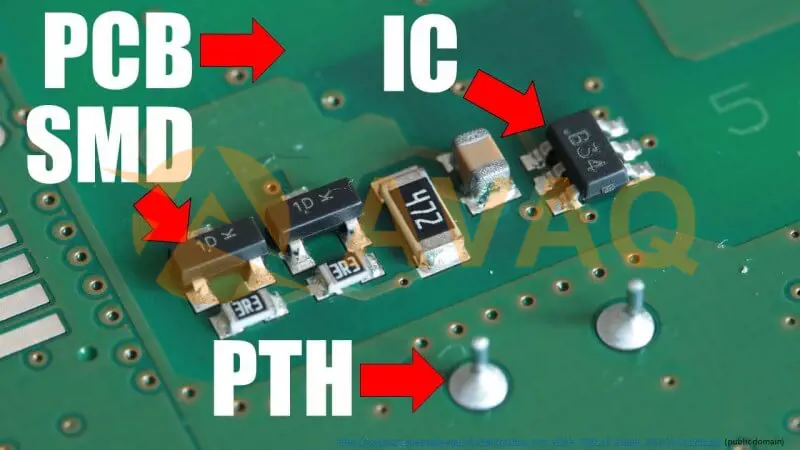

A Printed Circuit Board (PCB) is a flat board made of non-conductive material, typically fiberglass or composite epoxy, which serves as a platform for assembling and connecting electronic components. The board contains a network of copper traces or conductive pathways that enable the flow of electrical signals between the components.

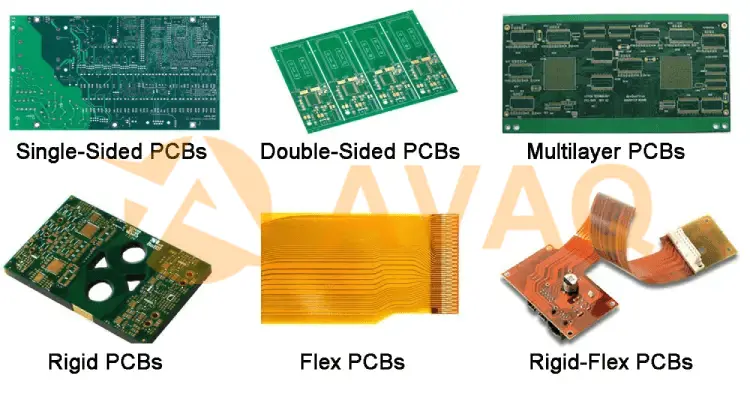

1. Types of PCB

In this article, our team will introduce 8 types of PCB for you,

1) Single-Sided PCB:

- Consists of a single layer of substrate material (typically fiberglass or composite epoxy) with conductive traces on one side and soldered components on the other.

- Suitable for simple circuits with fewer components and limited interconnections.

- Cost-effective and relatively easy to manufacture.

2) Double-Sided PCB:

- Contains conductive traces on both sides of the substrate, allowing for more complex circuits and increased component density.

- Components can be mounted and soldered on both sides of the board.

- Requires careful design considerations for proper trace routing and component placement.

- Through-hole plating or vias are used to establish electrical connections between the two sides.

3) Multilayer PCB:

- Consists of multiple layers of substrate material with conductive traces sandwiched between them.

- Provides higher circuit density, increased functionality, and improved signal integrity.

- Inner layers are connected using vias, which are small plated holes that allow electrical connections between different layers.

- Commonly used in complex electronic devices like computers, smartphones, and advanced industrial systems.

4) Rigid PCB:

- Made from rigid materials such as fiberglass or composite epoxy.

- Provides mechanical support and stability to the components.

- Suitable for applications where the board is not subjected to bending or flexing.

5) Flexible PCB:

- Utilizes flexible materials like polyimide or polyester.

- Allows the board to be bent, twisted, or folded, enabling it to fit into tight spaces or conform to non-planar surfaces.

- Used in applications where flexibility or vibration resistance is required, such as in wearable devices, automotive systems, and medical equipment.

6) Rigid-Flex PCB:

- Combines both rigid and flexible PCB sections.

- Offers a combination of mechanical stability and flexibility in a single board.

- Suitable for complex applications where both rigid and flexible sections are required, such as in folding smartphones or devices with moving parts.

7) High-Frequency PCB:

- Designed specifically for applications involving high-frequency signals, such as radio frequency (RF) communication or wireless devices.

- Features specialized materials and careful impedance matching to minimize signal loss and ensure accurate signal transmission.

8) High-Density Interconnect (HDI) PCB:

- Utilizes advanced manufacturing techniques to achieve higher component density and miniaturization.

- Involves microvias, blind vias, and buried vias for interconnection between layers.

- Enables smaller and more compact electronic devices with improved performance.

These are just a few examples of PCB types, and there are various variations and specialized designs available to meet specific application requirements. The choice of PCB type depends on factors like circuit complexity, space limitations, performance requirements, and cost considerations.

2. Application of PCB

Here are the applications of PCB,

|

PCB Model |

Application |

Manufacturer |

Description |

|

Arduino Uno |

Prototyping, Education |

Arduino |

Open-source development board for electronics projects. |

|

Raspberry Pi |

Internet of Things (IoT) |

Raspberry Pi |

Single-board computer for various computing applications. |

|

NVIDIA Jetson Xavier NX |

AI, Robotics |

NVIDIA |

High-performance embedded platform for AI applications. |

|

STM32 Nucleo |

Embedded Systems |

STMicroelectronics |

Development board for prototyping with STM32 microcontrollers. |

|

ESP32 |

Wireless Communication |

Espressif Systems |

Low-power Wi-Fi and Bluetooth module for IoT devices. |

|

BeagleBone Black |

Embedded Computing |

BeagleBoard.org |

Low-cost, community-supported development board. |

|

Intel NUC |

Compact Computing |

Intel |

Small form-factor computer for home and office use. |

|

Arduino Mega |

Robotics, Automation |

Arduino |

Microcontroller board with extended I/O capabilities. |

|

NVIDIA Jetson Nano |

AI, Edge Computing |

NVIDIA |

AI development kit for running deep learning algorithms. |

|

Teensy 4.1 |

Audio/MIDI Processing |

PJRC |

Microcontroller board with high-performance capabilities. |

Part 2. What is Integrated Circuit

An Integrated Circuit (IC), also known as a microchip or chip, is a miniaturized electronic circuit that consists of various interconnected electronic components, such as transistors, resistors, capacitors, and diodes, fabricated onto a single semiconductor material, typically silicon.

The concept of an integrated circuit revolutionized the electronics industry by enabling the integration of complex circuits onto a small chip. Before ICs, electronic circuits were constructed using discrete components, which required significant space, power, and manual assembly. With ICs, the components are fabricated directly onto the semiconductor material, allowing for compactness, increased functionality, and improved performance.

1. Types of Integrated Circuits

Integrated circuits can be classified into different types based on their construction and functionality:

1) Analog Integrated Circuits:

- Designed to process and amplify continuous electrical signals.

- Common applications include audio amplifiers, voltage regulators, and analog-to-digital converters.

2) Digital Integrated Circuits:

- Used for processing and manipulating binary information in the form of discrete on/off signals.

- Examples include microprocessors, memory chips, and digital logic gates.

3) Mixed-Signal Integrated Circuits:

- Combine both analog and digital circuitry on a single chip.

- Used in applications that require both analog signal processing and digital control, such as data converters, sensor interfaces, and communication systems.

4) Application-Specific Integrated Circuits (ASICs):

- Custom-designed ICs for specific applications or functions.

- They are tailored to meet the requirements of a particular application, offering optimized performance and reduced size compared to general-purpose ICs.

- ASICs are commonly used in fields like telecommunications, automotive systems, and consumer electronics.

5) System-on-Chip (SoC):

- Integrates all or most of the components of a complete electronic system onto a single chip.

- Includes microprocessors or microcontrollers, memory, input/output interfaces, and various other functions specific to the system.

- SoCs are widely used in smartphones, tablets, embedded systems, and IoT devices.

Further Reading: 7 Different Types of Integrated Circuit 2023

Part 3. Difference between PCB and Integrated Circuit (HOT!)

While both Printed Circuit Boards (PCBs) and Integrated Circuits (ICs) are integral components of electronic systems, they have distinct roles and characteristics. Here are the key differences between PCBs and ICs:

#1. Function and Purpose:

- PCB: A PCB serves as a platform for assembling and connecting electronic components. It provides mechanical support, electrical connections, and signal routing between components.

- IC: An IC is a miniaturized electronic circuit fabricated onto a single semiconductor material. It integrates multiple electronic components, such as transistors, resistors, and capacitors, onto a single chip, enabling complex functionality.

#2. Level of Integration:

- PCB: A PCB facilitates the interconnection of discrete electronic components. It provides a physical structure for mounting and connecting components but does not include active circuitry or complex functionality on its own.

- IC: An IC, on the other hand, integrates numerous electronic components onto a single chip. It contains active circuitry, logic gates, memory elements, and various other components necessary for specific functions. ICs can range from simple logic gates to complex microprocessors or memory chips.

#3. Manufacturing and Complexity:

- PCB: PCBs are typically manufactured through processes such as circuit design, layout, etching, and drilling. They involve the placement and soldering of discrete electronic components onto the board. PCB complexity varies based on the circuit design and number of components.

- IC: Integrated circuits are manufactured through semiconductor fabrication processes, involving highly precise and controlled manufacturing techniques. These processes include photolithography, etching, doping, and metallization to create intricate patterns and interconnections on the semiconductor material. ICs can be highly complex and densely packed with numerous components.

#4. Size and Form Factor:

- PCB: PCBs come in various sizes and form factors, ranging from small boards used in consumer electronics to larger boards in industrial applications. They can be single-sided, double-sided, or multilayered, depending on the complexity of the circuit.

- IC: Integrated circuits are typically much smaller in size compared to PCBs. They are designed to be miniaturized and compact, with components and interconnections fabricated on a single chip.

#5. Level of Customization:

- PCB: PCBs can be customized to accommodate specific circuit designs, component placements, and interconnections. They can be tailored to meet the requirements of different electronic systems and applications.

- IC: Integrated circuits are often designed and manufactured for specific functions and applications. While there are application-specific integrated circuits (ASICs), they still have limitations in terms of customization compared to PCBs.

Part 4. PCB VS Integrated Circuit: Advantages and Disadvantages

Here's a comparison of the advantages and disadvantages of PCBs and Integrated Circuits (ICs):

Advantages of PCBs:

Flexibility: PCBs offer design flexibility, allowing for customization and adaptation to specific circuit requirements.

Cost-effective: PCBs can be manufactured at a relatively low cost, especially for simple designs and high production volumes.

Repairability: In case of component failure, individual components can be easily replaced on a PCB, making repair and maintenance more straightforward.

Prototyping and Testing: PCBs enable rapid prototyping and testing of circuit designs before mass production, reducing time-to-market.

Suitable for complex systems: PCBs can accommodate complex circuit designs with a high number of components and interconnections.

Easier documentation and assembly: PCBs facilitate clear documentation and assembly instructions, making production and troubleshooting more efficient.

Disadvantages of PCBs:

Limited integration: PCBs do not integrate active circuitry on the board itself, relying on discrete components for functionality.

Size and space requirements: PCBs can be larger in size compared to ICs, requiring more physical space in electronic devices.

Signal loss and interference: With increasing complexity and high-frequency applications, signal loss and interference can occur due to longer trace lengths and improper routing.

Manufacturing complexity: Designing and manufacturing complex multilayer PCBs can be challenging and require specialized knowledge and techniques.

Limited miniaturization: PCBs have limitations in terms of miniaturization compared to highly integrated ICs.

Advantages of Integrated Circuits (ICs):

Miniaturization: ICs offer compactness and miniaturization, allowing for the integration of complex functionality onto a single chip.

High integration: ICs integrate numerous electronic components onto a single chip, reducing size, complexity, and interconnectivity issues.

Improved performance: Integrated circuits can provide enhanced performance due to reduced signal loss, shorter interconnections, and optimized layouts.

Power efficiency: ICs often consume lower power compared to discrete components, contributing to energy efficiency.

Higher reliability: ICs are less susceptible to failures caused by loose connections, electromagnetic interference, or mechanical stress due to their monolithic structure.

Disadvantages of Integrated Circuits (ICs):

Complexity and cost: Designing and manufacturing integrated circuits can be complex and costly, especially for custom or low-volume applications.

Lack of flexibility: ICs are generally not customizable once manufactured, limiting their adaptability to specific circuit requirements.

Repair and maintenance challenges: Repairing or replacing components in ICs is challenging, often requiring specialized equipment and expertise.

Development time: Designing and fabricating ICs may involve longer development cycles, including testing and verification stages.

Sensitivity to external factors: Integrated circuits can be more sensitive to environmental factors, such as temperature and voltage fluctuations, requiring proper thermal management and power supply considerations.

Part 5. Conclusion

In conclusion, PCBs and ICs are integral components of electronic systems, each serving a unique purpose and offering distinct advantages. PCBs provide a platform for interconnecting electronic components, enabling the creation of complex circuits and systems. On the other hand, ICs integrate multiple electronic components onto a single chip, providing compactness, efficiency, and enhanced functionality.

By understanding the differences between PCBs and ICs, you can effectively leverage their strengths and select the most suitable component for your electronic projects. Stay updated with the latest advancements, explore datasheets and application notes, and make informed choices when designing electronic systems. Embrace the benefits of both PCBs and ICs, and unlock endless possibilities in the realm of electronics.

FAQ

FAQ

- Can PCBs be used without integrated circuits?

- Yes, PCBs can be used without integrated circuits. PCBs are commonly used in various electronic devices and systems, including those that incorporate discrete electronic components, such as resistors, capacitors, and transistors, rather than integrated circuits.

- Are PCBs and ICs interchangeable terms?

- No, PCBs and ICs are not interchangeable terms. PCB refers to the physical board that provides electrical connections and mechanical support, while IC refers to the integrated circuit itself, which is a small electronic device containing interconnected electronic components on a chip.

- Can ICs be directly mounted on a PCB?

- Yes, ICs can be directly mounted on a PCB. This is typically done by soldering the IC's leads or pads to corresponding pads or traces on the PCB. However, in some cases, ICs are mounted on specialized packages or modules, which are then soldered onto the PCB.

- What is the purpose of a PCB?

- The primary purpose of a PCB is to provide a platform for mounting and interconnecting electronic components. It allows for efficient and reliable electrical connections between components, provides mechanical support, and helps organize the circuit layout for optimal performance and manufacturability.

Popular Industry Focus

Popular Industry Focus

Hot Products

-

![OPA2227U/2K5]()

OPA2227U/2K5

TI

General Purpose Amplifier 2 Circuit 8-SOIC

-

![DP83848YB]()

DP83848YB

TI

1/1 Transceiver Ethernet 48-LQFP-EP (7x7)

-

![PCM2704]()

PCM2704

TI

98dB SNR Stereo USB2.0 FS DAC with line-out and S/PDIF output, Bus/Self-powered (Ext. ROM Interface)

-

![TPS79601DRBR]()

TPS79601DRBR

Texas Instruments

Voltage-controlled current source

-

![TLV431ACDBZR]()

TLV431ACDBZR

TI

Shunt Voltage Reference IC Adjustable 1.24V 6 VV ±1% 15 mA SOT-23-3

-

![TPS62743YFPR]()

TPS62743YFPR

TI

Buck Switching Regulator IC Positive Programmable 1.2V 1 Output 300mA 8-XFBGA, DSBGA

Related Parts

-

![LXT905LE]()

LXT905LE

CORTINA SYSTEMS INC

Ethernet Transceiver, CMOS, PQFP32, MO-136BC, LQFP-32

-

![MC68901P]()

MC68901P

NXP Semiconductor

NXP Semiconductors

-

![SII7181CMHU]()

SII7181CMHU

Lattice Semiconductor

High-definition video solution for PC Monitors and DTVs

-

![HMC6000LP711E]()

HMC6000LP711E

Analog Devices Inc.

RF Transmitter 57GHz ~ 64GHz 16dBm PCB, Surface Mount Antenna 60-VFQFN Exposed Pad

-

![WRL-12577]()

WRL-12577

SparkFun Electronics

SPARKFUN BLUETOOTH MODEM

-

![SAR-713]()

SAR-713

ICP DAS USA INC

Transceiver Module Antenna Not Included DIN Rail

-

![RN42-I/RM615]()

RN42-I/RM615

Microchip Technology

Bluetooth Bluetooth v2.1 +EDR, Class 2 Transceiver Module 2.4GHz Integrated, Trace Surface Mount

-

![XB2B-WFPS-001]()

XB2B-WFPS-001

Digi

WiFi 802.11b/g/n Transceiver Module 2.4GHz Integrated, Trace Surface Mount

-

![LR1120IMLTRT]()

LR1120IMLTRT

Semtech Corporation

RF Transceiver Low Power Wi-Fi/GNSS Scanner + LoRa Transceiver

-

![ATBTLC1000-MR110CA]()

ATBTLC1000-MR110CA

Microchip Technology

Bluetooth Modules - 802.15.1 Smart Connect Moudle Mu-T

-

![XPW100100B-01]()

XPW100100B-01

Lantronix, Inc.

WiFi 802.11b/g/n Transceiver Module 2.4GHz

-

![SPWF01SC.11]()

SPWF01SC.11

STMicroelectronics

Serial to Wi-Fi Server IEEE 802.11b/g/n

-

![RC1180-MBUS3]()

RC1180-MBUS3

Radiocrafts AS

General ISM < 1GHz Wireless M-Bus Transceiver Module 868MHz Antenna Not Included, Castellation Surface Mount

-

![BGM13S32F512GA-V2R]()

BGM13S32F512GA-V2R

Silicon Labs

Bluetooth Bluetooth v5.0 Transceiver Module 2.4GHz Integrated, Chip Surface Mount

-

![ENW-89841A3KF]()

ENW-89841A3KF

Panasonic Electronic Components

Bluetooth Modules - 802.15.1 PAN1322 Bl v2.1 +EDR SPP with Antenna

Update Time: Jun 26, 2023 Consumer Electronics

Update Time: Jun 26, 2023 Consumer Electronics